EMITEC UREA DOSING PUMP OPERATING CONDITIONS

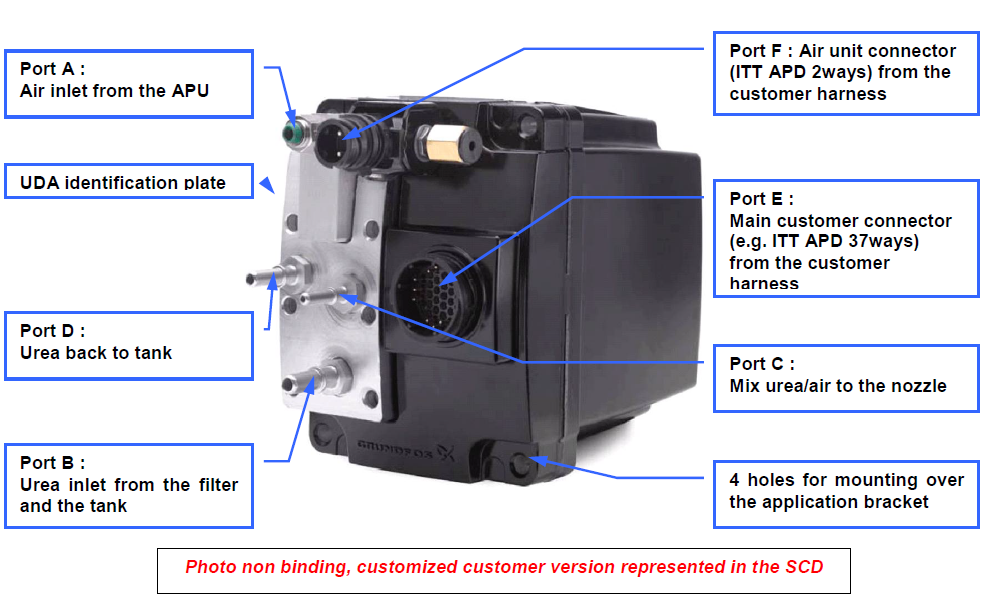

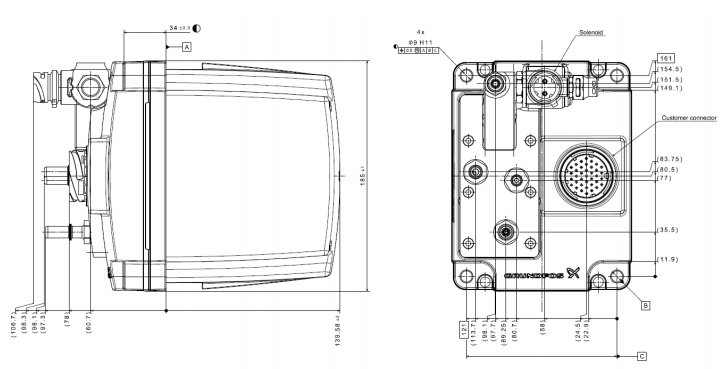

2.Integration dimensions and physical parameters

2D overall dimension drawings and 3D volume files in IGS, Step and Catia format are available on request.

The dry pump weight is 4.6 Kg excluding shipping hardware.

The Dosing unit is designed to be mounted on the vehicle chassis, the dosing unit is not designed to stand into the engine

bay.

3.Operating conditions

The Dosing unit is specified to dose from –40C to +85C as ambient temperature

Important note: Whatever the ambient temperature is:

THE SOLENOID VALVE COIL MAY BE VERY HOT AND THE CONTACT WITH HUMAN SKIN DURING

AND AFTER OPERATION MUST BE AVOIDED

3.1 Standard priming sequence

At engine key ON the UDA is receiving the starting procedure. The UDA accuracy is sensitive to the presence of air in the

suction line. The keying on operation allows the ECM to deliver to the UDA a message starting the priming sequence.

The priming sequence is running for 30”, it can be repeated up to 20 times until the priming operation is properly

completed. If the UDA is not properly primed after the sequence then a telegram no air or no urea is sent to the ECM.

Specific setup can be implemented but customer will be responsible for the doser behaviour.

3.2 Running phase

The dosing unit delivers the required amount of urea. The air is always flowing to the nozzle

3.3 Standard purging phase

When the engine is key OFF, the air is flowing to the nozzle to purge the nozzle line. The purging sequence duration is 30

seconds. If the supply voltage is switched off before the end of the purging phase then the dosing unit records an

incomplete purge sequence.

Specific setup can be implemented but customer will be responsible for the doser behaviour.