Urea Dosing System.Fluids

The UDA is designed to operate only with Urea diluted with water in the ratio of 32.5% in weight as defined in the ISO

22241-1 Standard.

The system has to supply the UDA with liquid urea at 5°C minimum and +55 °C maximum (Urea temperature can reach

+85°C but only in peaks (duration ~ 30 min maximum, 24 hours minimum between each peak, total duration: 500h).

Heated lines are recommended to maintain the media temperature. The integrator has to validate the heating efficiency to

allow the doser to release the pressure when turning off the system. If this is not possible the integrator shall implement

an safety procedure by shutting off the doser before the lines got frozen to allow the pressure release.

Take contact with Emitec if other fluids would be used.

THE UREA SUPPLY FROM THE TANK MUST BE FILTERED, NO PARTICLES HIGHER THAN 100µm

ARE ALLOWED TO ENTER THE DOSER.

BEFORE TO OPERATE THE DOSER, UREA AT THE PORTS HAS TO BE WITHIN THE SPECIFIED

TEMPERATURE RANGE, FREE OF CRISTALS AND ICE.

Over customer filter lifetime, pressure loss shall not exceed more than 80mbar

The cleanliness test methods should be according to ISO 16232

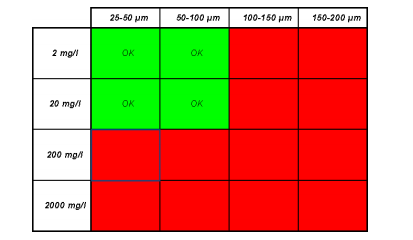

Doser contamination resistance:

In the table, figures are given by using contaminant nature according to ISO 12103 A3.

IT IS THE USER RESPONSIBILITY TO CHECK ABOUT CORRELATION WITH STANDARD REGARDING

CONTAMINANT CHARACTERISTICS (NATURE, DENSITY AND SIZE).

The flow into the suction line connected to port B of the UDA appears only during the UDA suction phase. The suction

flow is pulsated with a max peak flow about 25 liters/hour whatever the dosing demand is.

The suction flow pulse frequency increases with the dosing volume.

The suction line with all its accessories as fitting connection has to be designed to be absolutely sealed working in

depression.

The return line from port D has to be designed in such way that the return line pressure never exceeds and absolute

dynamic pressure of 1,5 bars. If the return line pressure measurement is performed on the installation, the pressure gage

has to be able to catch dynamic pressure pulses.

THE UREA FLOW INSIDE THE SUCTION LINE TO PORT B IS MAX. 25 LITERS PER HOUR DEPENDING

ON REQUESTED DOSING FLOW

CONTAMINATION COULD PREVENT THE UDA FROM OPERATING

5.2 Air

The UDA is designed to operate with dry clean air coming out from an Air Processing Unit. Maximum temperature of air

must be as low as possible to avoid crystals formation.

The UDA air pressure inlet at port A have to be kept between 6 to 10 bars for proper operation.

The UDA could operate with air inlet pressure up to 12 bars peak wise.

Nozzle characteristics as per DBE 567. The nozzle design is under customer’s responsibility , nevertheless it has to

match with the characteristics as per DBE 567. Changes will request to be tested to see influence on droplet size, air

consumption, backpressures,…

AIR SUPPLY FROM APU MUST BE COMPLIANT WITH STANDARD ISO 8573 CLASS 2 FOR DEW

POINT AND CLASS 3 FOR OTHERS AIR PROPERTIES

IT IS CUSTOMER RESPONSIBILITY TO STOP THE SYSTEM WHEN AIR PRESSURE IS OUT OF

SPECIFIED RANGE

Air Flow consumption for specific application as nozzle or backpressure can be estimated by Emitec on request.

Note that the air flow decrease when the urea flow increase.

AIR IS ALWAYS FLOWING (PERMANENT AIR CONSUMPTION) WHEN THE UDA IS ON DOSING MODE

EVEN WHEN THE PUMP IS NOT DOSING UREA