Urea Dosing System Air Assisted Installation and Operating Instructions UDA 7.5- Integration specifications

Integration specifications

The UDA is a high precision device; all care must be taken:

To avoid direct exposure to heat radiation from the exhaust pipe and catalyst.

To avoid mechanical shock or stress during dosing unit handling or assembly.

Dosing unit location see § 2

Grounding and earthling: see caution § 4.1.

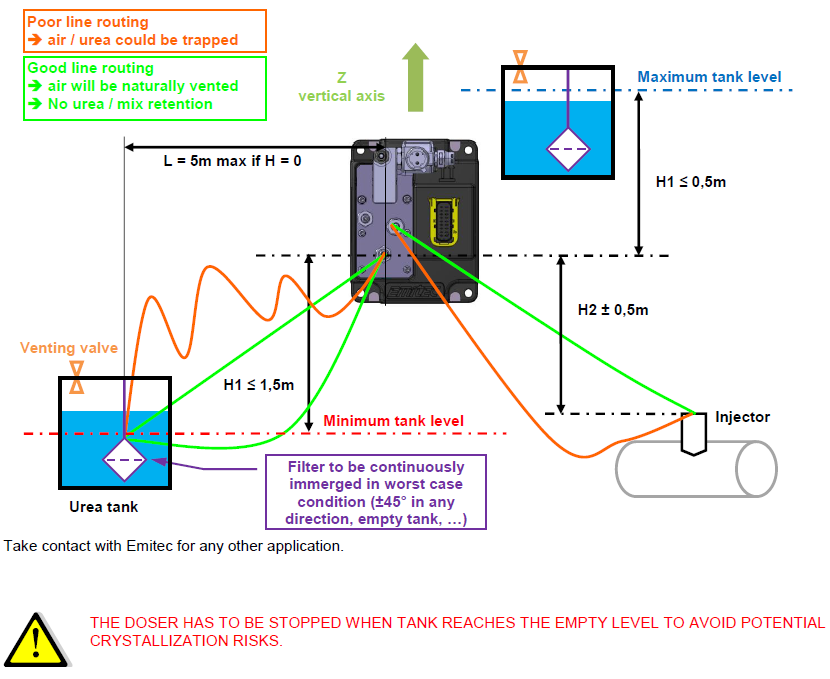

The UDA accuracy is very depending on the UDA urea suction line design and operating condition. The UDA suction line

connected to the port B as to be fully tight, any leakage at the suction line will give a very big negative impact to the UDA

accuracy, the suction line may be under depression while the UDA is sucking.

Due to urea degassing property and the pump operating principle it is from the most importance to avoid all pipe elbows

over the port B of the UDA at the suction line connected to port B.

In general matter the UDA integration as to be made in such way that no air can be trapped into the suction pipe.

Please note that the urea degases on it own with time.

The UDA has to be located over the maximum urea tank level except if the following design is fulfilled.

The length of the suction line has to be as little as possible in order to reduce the effect of degassing.

The use of a foot valve (check valve at the suction pipe end is highly recommended)

The dynamic pressure lost measured at the dosing pump port B has to be kept lower than 50 mbar.

The pressure at dosing port B has to be kept between 800mbar and 1100 mbar absolute including the dynamic pressure

lost.

urea pump Integration specifications