UREA DOSING PUMP PERFORMANCE

The digital electronic doser control makes the UDA extremely fast to achieve the desired flow, within repeatability of 1% of

desired volume at steady state standard conditions at witch the pump is calibrated as 20°C ambient and liquid

temperature for instance.

THE UDA ACCURACY IS DIRECTLY DEPENDENT TO THE HYDRAULIC IMPEDANCE AT THE PUMP INLET; IT IS FROM THE MOST IMPORTANCE TO FULFIL SPECIFICATIONS OF THIS DOCUMENT TO REACH EXPECTED PERFORMANCES.

FOREIGN PARTICLES MAY DRIVES TO INCONSISTANT OPERATION WITH LOW SUCTION CAPACITY AND LOW PERFORMANCES AS REPEATABILITY AND ABSOLUTE FLOW, MALFUNCTION.

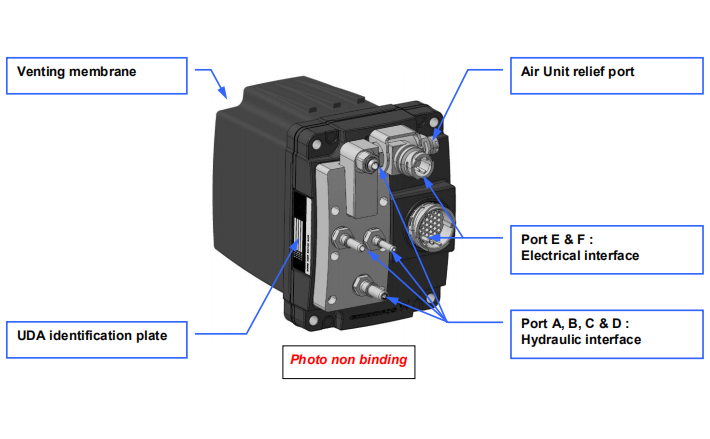

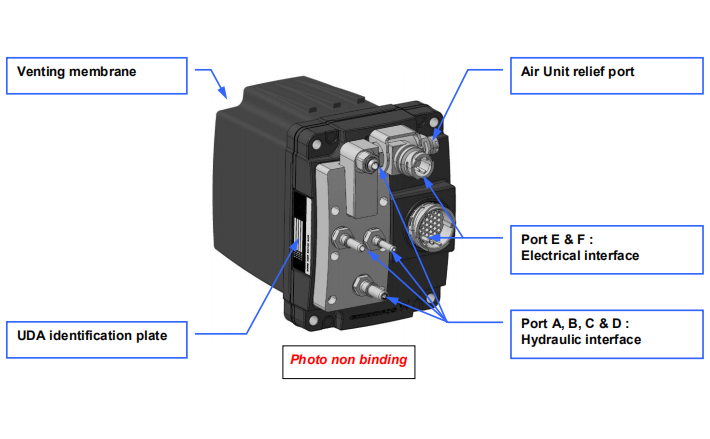

7.1 UDA painting

The UDA is designed to accommodate painting, the main frame and the enclosure are made of high-pressure die casting

aluminium material.

WHEN PAINTING THE UDA, SPECIAL CARE MUST BE TAKEN REGARDING GROUNDING AND

EARTHING; SEE CAUTION §4.1

WHEN PAINTING THE UDA ON THE TRUCKS CHASSIS, THE FOLLOWING PARTS MUST BE

PROTECTED:

HYDRAULIC PORTS : A, B, C & D

ELECTRICAL PORTS: E & F

VENTING MEMBRANE

IDENTIFICATION PLATE

AU RELIEF PORT

7.2 Dismounting and storage from system

Special care must be taken when the UDA is removed from the system.

Dismounting the UDA from the system should start by removing the hydraulic connection B,C & D to avoid pollution with

urea into the air inlet port A and the connector receptacles.

The nozzle line could be at air system pressure, insure that not pressurized air is pressurized between a collapsed nozzle

and the UDA, release the air pressure before dismounting the air connection to port A and the nozzle connection to port

Do not intend to introduce any tools into the UDA hydraulic ports or connector housing, the connector’s terminals must be

protected with appropriate plastic cap.

Check that no urea can be sprayed over the connector’s terminals before removing the electrical connections.

In case of Urea projection, carefully flush the unit with pure medium water to remove the urea and to avoid crystals builds

Dry the UDA connectors in order to check that no urea crystals are remaining inside the connector receptacle.

WHEN THE UDA HAS BEEN DISMOUNTED INSURE THAT THE UDA IS PROPERLY CLEANED UP BY

FLUSHING MEDIUM WATER FROM PORT B TO PORT D.

IN NON OPERATING CONDITON, IT IS VERY IMPORTANT TO SEAL THE 4 UDA POTS A, B, C, & D

WITH APPROPRIATE PROTECTIVE CAP TO PROTECT THE UDA FROM EXTERNAL POLLUTION, UREA

POLLUTION AND POTENTIAL CRYSTAL BUILD-UP.

THE SOLENOID VALVE COIL MAY BE VERY HOT AND THE CONTACT WITH HUMAN SKIN DURING

AND AFTER OPERATION MUST BE AVOIDED

NEVER TRY TO DISMOUNT YOURSELF THE COVER OR ONE OF THE PUMPHEAD SCREWS.

UDA ASSEMBLY REQUIRES USE OF MANY SPECIFIC PROCEDURES AND FACTORY CALIBRATION.