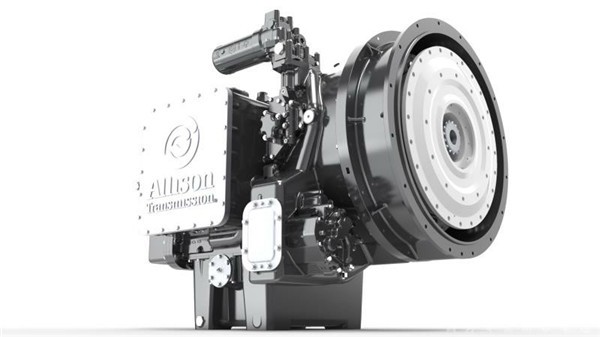

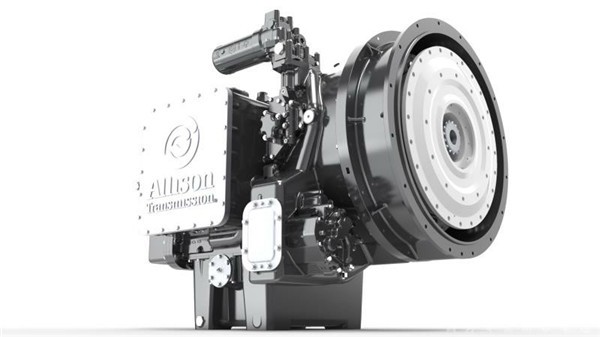

Allison launches a new generation of hydraulic fracturing gearbox

According to bus.com, on June 7, 2021, Allison Transmission, a leading designer and manufacturer of commercial vehicle drive solutions, and the world’s largest manufacturer of fully automatic transmissions for medium and heavy commercial vehicles, announced the launch of a revolution. FracTran, a hydraulic fracturing gearbox.

FracTran is a brand new oilfield series gearbox designed to meet the unique and evolving performance requirements of the hydraulic fracturing industry. This new-generation solution combines feedback and suggestions from our customers and analysis of operating condition information accumulated by Allison in the development and application of this product for decades. This important front-end effort ensures that FracTran will provide differentiated value, meet the changing needs of Allison customers, and fulfill the Allison brand promise to provide the world’s most reliable and valuable drive solutions

“As fracturing fleets and operators demand changes in oilfield production, high output and high profitability, their demand for equipment is that the greater the horsepower, the better, the equipment is smaller and lighter to reduce the carbon footprint, and can be faster and deeper. The ground reaches the bottom of the oil well. As their personal partner, Allison and customers innovate and develop together,” said John Coll, senior vice president of global marketing, sales and service for Allison Transmission. “Allison has been committed to serving our energy customers and invested a lot of resources to bring FracTran, the product they really need.”

According to current market demand, Allison will launch FracTran with an input power of 3,300 horsepower and an input torque of 10,000 pound-feet. However, FracTran can reach 3,500 horsepower without hardware changes. This sturdy hydraulic fracturing gearbox will provide unparalleled performance under high pressure conditions in the harshest operating environments. The main advantages and specifications of FracTran are high reliability. The design life of the gearbox is as long as 25,000 hours. There is no need to replace hard parts during overhaul, which reduces the total cost of ownership. It is equipped with eight gear shifts and provides a variety of speed ratio options. To meet the unique needs of customers. In addition, FracTran also provides filter element and oil life diagnosis, control modules installed on the gearbox, torsional vibration diagnosis and an on-board telematics system.

Allison’s commitment to quality and customer support goes beyond the use of FracTran hardware. FracTran will

Supported by a network of more than 1,400 Allison authorized dealers and distributors. Each location is equipped with specialized tools and equipment, as well as a team of trained and certified technicians to ensure that FracTran provides the most optimized total cost of ownership by minimizing downtime.

Recently, Allison held an event at the global headquarters in Indianapolis, which kicked off the FracTran road show. In the next few months, the company will visit dozens of cities in North America to showcase FracTran to our valued customers and industry partners in preparation for the start of production in 2023.