ZYF Vehicle LNG Leak Detection and Engine Room Temperature Alarm Device AL-101

ZYF Vehicle LNG Leak Detection and Engine Room Temperature Alarm Device AL-101 Parameter Configuration

Vehicle LNG leak detection and engine room temperature alarm device consists of LNG leak detector, temperature sensor and alarm host. The natural gas leak detector is installed in the dangerous area (the place where LNG is present), the temperature sensor is installed in the engine room or the natural gas storage tank compartment, and the alarm host is installed in the instrument panel. When the liquefied natural gas leakage reaches the set alarm concentration, an audible and visual alarm will be issued; the host panel can display the detected temperature value in real time, and an audible and visual alarm will be issued when the temperature exceeds the set value. For a system composed of multiple detectors, the red warning light corresponding to the detector can indicate the specific gas leak point. When the detector or temperature sensor fails or the connection with the alarm host fails, the fault alarm can be automatically carried out. The panel integrates a self-check button, which can check the working status of the alarm host at any time.

一、Matters needing attention

According to the environment in which this product is used, to ensure safety, please implement regular inspections. The inspection period is 1-3 months. Check whether the alarm host and detector are operating normally.

Spot inspection method: use spot inspection gas or liquefied natural gas to perform spot inspection on the detector to simulate leak action. The detector should avoid the impact of man-made high-concentration liquefied natural gas, otherwise the sensitivity of the gas sensor will be reduced for a short time. Please avoid contamination of silicon components during use to prevent damage to the detector! In the event of a liquefied natural gas leak, the host will give an audible and visual alarm. It is necessary to stop the vehicle as soon as possible and turn off the power supply of the whole vehicle, find the leaking point immediately, and take measures such as closing the valve and ventilating. It is strictly forbidden to unplug and plug the connector between the alarm host and the detector when the power is on, otherwise the internal chip of the system may be damaged. The detector should be installed as far away as possible from oily, high-temperature and high-humidity environments! If the sensor in the detector is damaged or invalid, it must not be replaced by oneself, and must be sent to the manufacturer’s designated point for inspection and repair.

二、Connection method

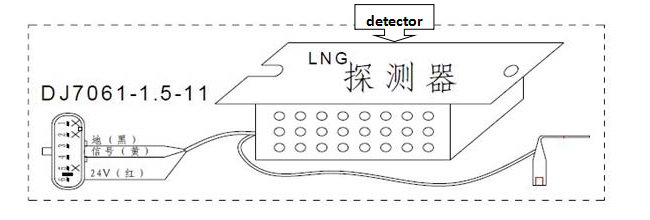

1、Detecto

Connect the wiring harness of the detector to the car power supply and the alarm host as defined in the figure below. The red wire of the detector is connected to the 24V power source output by the host, the black wire is connected to the vehicle power ground (GND), and the yellow wire is connected to the signal input terminal of the alarm host through the body harness.

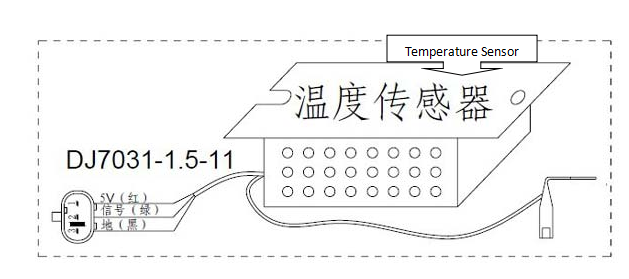

2、Temperature sensor

Connect the temperature sensor to the signal input terminal of the alarm host through the body harness. The red wire of the sensor is connected to the 5V power output of the host, the black wire is connected to the power ground (GND) of the host, and the green wire is connected to the temperature signal input terminal of the host.

Note: It is forbidden to directly connect the input wire of the temperature sensor to the 24V power supply or the power ground wire!

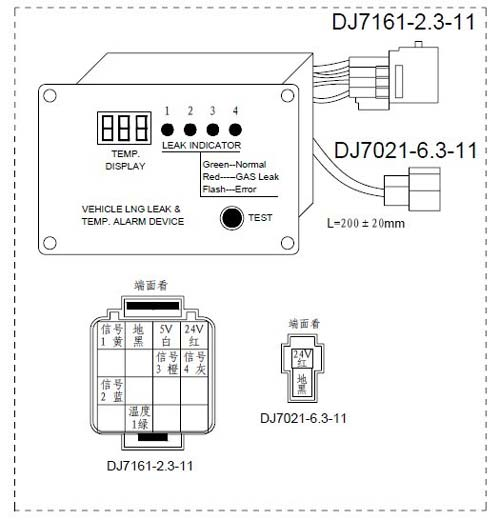

3、Alarm host

Connect the red wire of the alarm panel’s 2-core connector to the car’s ACC power supply; connect the black wire to the negative electrode of the car battery; connect the white, black, and green wires in the alarm panel’s 16-core connector to the corresponding ends of the temperature sensor, respectively. The red, yellow, blue, orange, and gray wires in the 16-pin connector are respectively connected to the corresponding ends of each detector. The red wire is the 24V power output from the host and must be connected to the power input of each detector.

For a single detector, only the red and yellow wires need to be connected; 2 detectors need to be connected to the red wire and yellow and blue wires; 3 detectors need to be connected to the red wire and yellow, blue, and orange wires; 4 detectors need to be connected all .

Note: The general product is configured according to the standard configuration of one alarm host, four natural gas detectors and one temperature sensor. Other configurations need to be customized

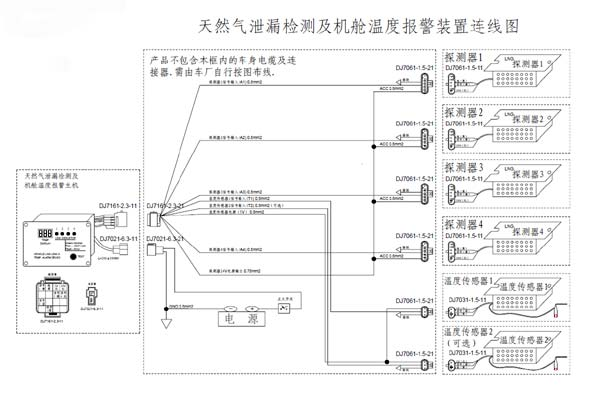

4、System connection diagram

三、Three, installation method

1、Detector

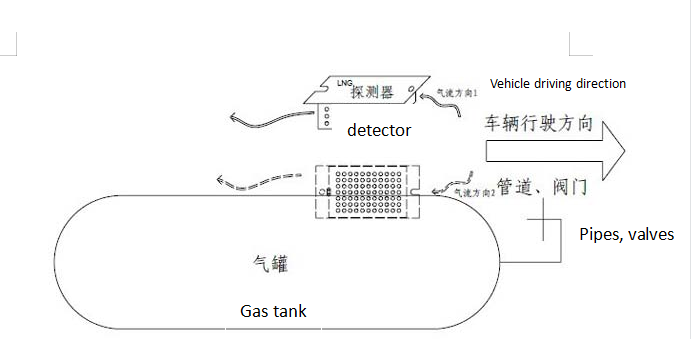

Determine the installation location of the detector according to the on-site leakage pressure, the possible leakage per unit time, the direction of the vehicle, and the air flow channel. The specific gravity of natural gas is less than that of air, and the detector should be installed at an appropriate height under the ceiling of the monitoring point, with the installation bottom plate facing upwards. It is recommended to set up detectors in places where natural gas is easy to accumulate, such as partially ventilated dead corners. If there is a hidden danger of micro-leakage, the detector setting point should be close to the leaking point; if there will be a large number of explosive leaks, the setting point should be appropriately far away from the leaking point. The following installation method is recommended for natural gas detectors, with the bottom plate facing up or on the side walls above the pipes and valves, and backing a certain distance according to the direction of the vehicle to facilitate natural gas leak detection.

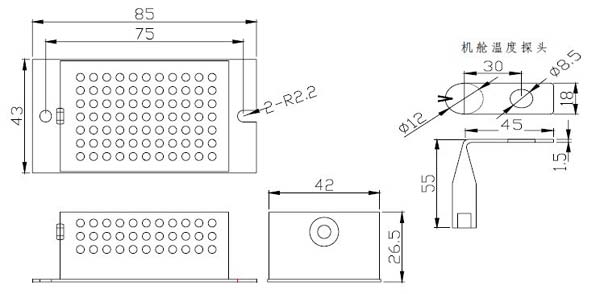

2、Temperature sensor

Fix the L-type temperature probe with a φ8 screw on the part where the temperature needs to be detected, and fix the sensor part in a suitable position. Keep the sensor parts away from high temperature parts as much as possible!

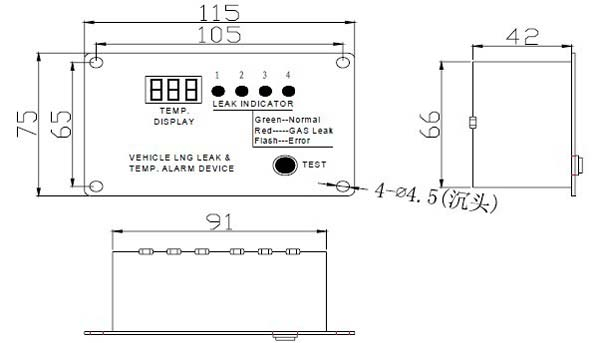

3、Alarm host

Fix the alarm host at a suitable position on the instrument panel with four φ4 countersunk screws.

四、Trigger and function description

After correctly connecting and fixing the vehicle liquefied natural gas leakage and engine room temperature alarm device according to the diagram, turn on the ACC power supply, the alarm host is initialized, and the digital tube displays 000, 111, 222, 333, 444, 555, 666, 777, 888, 999 Then the temperature of the point to be measured is displayed. The corresponding LED lights of the detector will light up sequentially from left to right, and enter the normal monitoring state after 30 seconds. If the corresponding detector is normal, the green light will be displayed; if the detector or the connection is faulty, the corresponding red light will flash. The detector needs to be warmed up for a period of time after it is energized.

In the event of a liquefied natural gas leak and the concentration detected by the detector exceeds the set alarm value, the detector outputs a leak alarm signal to the alarm host, the alarm host buzzer emits a “beep beep beep” alarm sound, and the corresponding red LED The lamp lights up. When the natural gas concentration is lower than the alarm value, the buzzer will be turned off and the corresponding LED light will be green.

When the detected temperature is higher than 105 degrees, the temperature value displayed by the digital tube starts to flash, and the buzzer emits a “beep beep” alarm sound. If the temperature continues to rise and reaches 115 degrees, the buzzer emits a rapid “Beep beep beep” sound. During use, press the self-check button on the panel, the host displays “888”, the LED lights are four yellow lights, flashing at the same time, and the buzzer emits a “beep beep beep” alarm sound. After releasing the self-check button, the host resumes normal display.

五、Dimensions

1、Alarm host

2、Detector and temperature sensor, temperature probe

六、Technical specifications

Rated voltage 24VDC (9V~32VDC) (alarm host + detector)

5VDC±5% (temperature sensor, output by the alarm host)

Working current is less than 150mA (alarm host)

Less than 40mA (detector)

Less than 15mA (temperature sensor, output by the alarm host)

Working temperature -20℃~70℃ (detector + temperature sensor)

0℃~130℃ (temperature probe)

-40℃~85℃ (alarm host)

Storage temperature -20℃~70℃ (detector + temperature sensor)

Engine room temperature probe

-40℃~150℃ (temperature probe)

-40℃~85℃ (alarm host)

Alarm mode Digital tube, LED and buzzer alarm

Fail type Sensor failure, detection circuit open circuit, short circuit

Detect gas Liquefied natural gas

Detection range 1%-100% (methane)

Alarm concentration 10%LEL±2% (methane) (5000ppm)

The response time is less than 20 seconds

The recovery time is less than 30 seconds

Temperature error ±2℃

Dimension 115mm×55mm×42mm (alarm host)

85mm×43mm×26.5mm (detector + temperature sensor)

55mm×51mm×18mm (temperature probe)

The weight is less than 400g (alarm host)

150g (detector)

200g (temperature sensor, including temperature probe)

Alarm sound pressure 65dB (500mm, A-weighted)