The working principle and important components of SCR tail gas treatment system

Important components of SCR

SCR definition and benefits

SCR namely “SelectiveCatalyticReduction” mean in Chinese for the selective catalytic reduction. It refers to the use of vehicular urea aqueous solution in the exhaust pipe due to the engine high temperature combustion of nitrogen oxide (NOx) into harmless nitrogen and water, a tail gas treatment technology. It has been adopted by Dongfeng Cummins engine because of its advantages such as saving fuel consumption, greater potential of emission upgrade and less influence on the design of the cab.

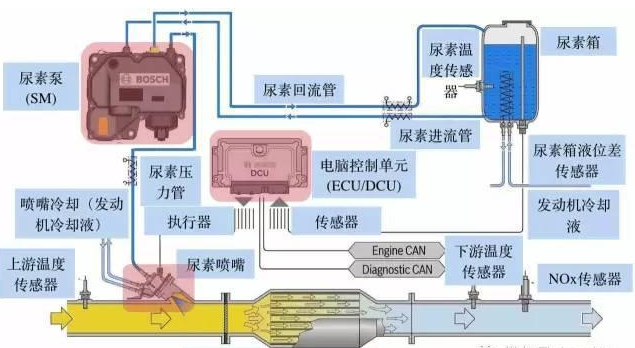

Important components of SCR

Common SCR post-processing system is usually composed of engine emission control module, OBD on-board diagnostic module, vehicle urea injection module, SCR catalytic converter module and signal sensor. Compared with other brands of engines, the SCR exhaust treatment system of Dongfeng Cummins does not integrate the engine emission control module with the engine computer ECU. It has the characteristics of faster signal transmission, more sensitive reaction of jet pump, more accurate control of urea injection volume and higher utilization rate of urea.

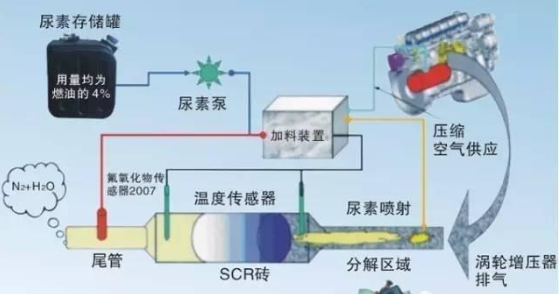

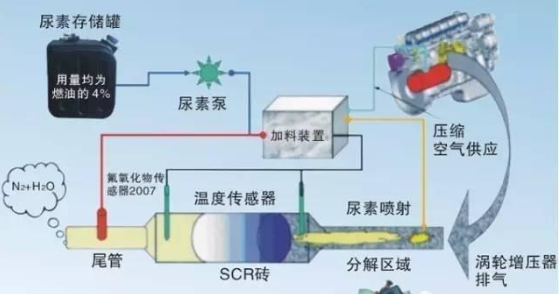

How SCR works

It employs the EcoFit Cummins urea injection system through the SCR body front end of the temperature sensor input signal with the SCR minimum operating temperature (200). C) Deterine the timing of urea injection, and ensure the heating time of the NOx sensor according to the temperature sensor signal at the back end of the SCR body. It can not only ensure no waste of urea solution, but also ensure that the NOx sensor always keeps the best working state, and improve the utilization rate of urea.

SCR urea nozzles

The urea injection system nozzle is a component that requires high durability to spray the atomized urea and air mixture through the catalyst carrier. Due to the harsh working environment in the exhaust pipe, it needs to prevent the clogging of carbon particles to the maximum extent. The characteristic of the Cummins nozzle is that the center of the tail gas flow is injected. The nozzle adopts the design of large throttling area to make full use of the air flow to self-clean, minimize the risk of urea crystallization and improve its impurity tolerance.