Ten Steps for Speed Regulation of Generator Sets

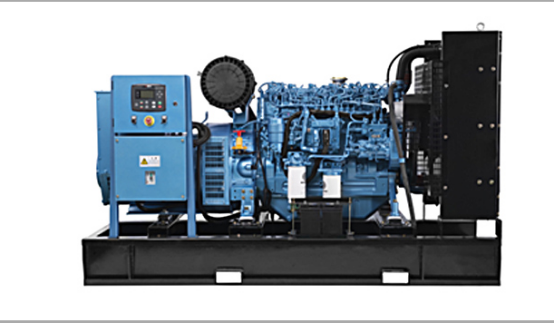

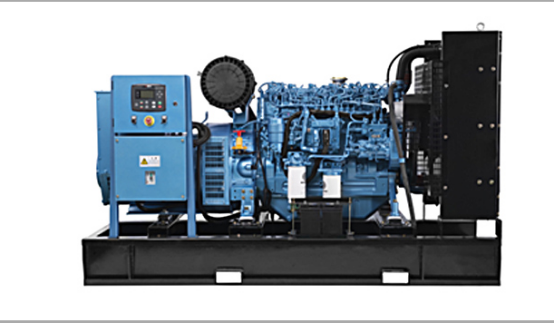

Diesel generator set is a kind of power generating device with quick start, convenient operation and maintenance, low investment, and strong adaptability to the environment. It is mainly used for the power supply of various power sources and emergency power sources, and can also be used for the power supply of electric propulsion systems, and its importance is self-evident. Therefore, the commissioning work before the generator set works is also indispensable.

1. Add water

First turn off the drain valve, add clean drinking water or purified water to the position of the water tank mouth, and close the tank cover.

Two, add oil

3. Engine oil is divided into summer and winter. Different engine oils are used in different seasons. For diesel engines, add No. 8 or No. 11 oil in winter and No. 14 oil in summer.

In the process of adding engine oil, pay attention to the vernier scale until the engine oil is filled to the position where the scale of the vernier scale is full. Cover the engine oil cap. Do not add too much. Excessive engine oil will cause the phenomenon of draining and burning engine oil.

4. Distinguish between incoming and outgoing oil

To ensure that the machine’s oil intake is clean, half of the diesel fuel should be allowed to settle for 72 hours. Do not insert the oil in the position of the oil cylinder, so as not to suck dirty oil and block the oil pipe.

Five, pump diesel

First loosen the nut of the hand oil pump, hold the handle of the hand oil pump of the diesel generator set, and evenly pull and press until the oil enters the oil pump.

6. Connect to the starter motor

Distinguish the positive and negative poles of the motor from the positive and negative poles of the battery. The two batteries should be connected in series to achieve a 24V effect. Connect the positive pole of the motor first. When connecting the positive pole, do not let the terminal touch other wiring sections. Then connect the negative pole of the motor, and be sure to connect it firmly to avoid sparking and burning the wiring section.

Seven, air switch

Before the machine is started or when the machine does not enter the power supply state, the switch should be in a separate state. There are four terminals at the bottom of the switch. These three are three-phase live wires. The Cummins generator set is connected to the power line, and the independent one next to it is zero. The power source that is in contact with any one of the live wires and the neutral wire is 220V lighting power. Do not use one that exceeds one-third of the rated power of the generator.

Eight, the instrument part

1. During use, the used power can be accurately read by the ammeter

2. The voltmeter can detect the output voltage of the motor

3. The frequency meter must reach 50Hz, which is the basis for detecting the speed

4. The current and voltage conversion switch is used to detect the data of the motor instrument

5. The oil pressure gauge, detecting the operating oil pressure of the diesel engine, should not be less than 0.2 atmospheres at full speed

6. Tachometer, the speed should be at 1500 revolutions per minute

7. The water temperature meter, during use, cannot exceed 95 degrees, and the oil temperature generally cannot exceed 85 degrees.

Nine, start

Turn on the ignition switch, press the button, release the development motor unit after turning on the car, run for 30 seconds, flip the high and low speed switches, the machine will slowly rise from idle to high speed, and check the readings of all meters. Under all normal conditions, the air switch can be closed and the power transmission is successful.

10. Parking

First turn off the air switch, cut off the power supply, adjust the diesel engine from high speed to low speed, let the machine idle for 3-5 minutes, and then turn off the machine

.