Differences between DOC, DPF and SCR Filters

There are at least two differences between DOC, DPF and SCR Filters.

Regeneration

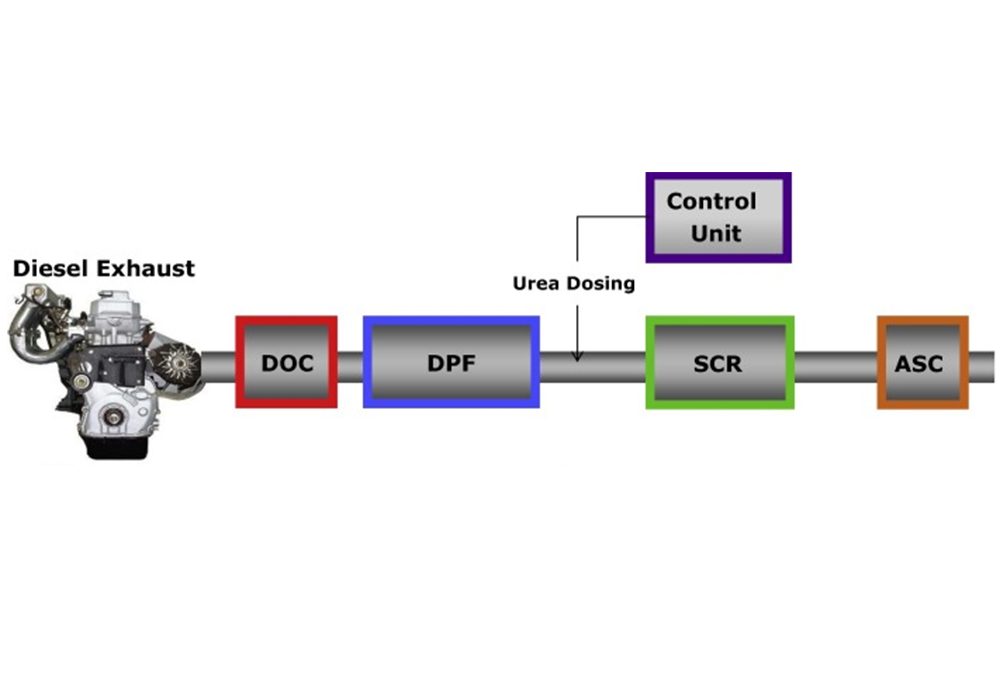

The DOC is the first device in the after treatment system. It is a flow through filter that contains precious metals to start the oxidation of hydrocarbons, carbon monoxide and unburned fuel and oil. Both the DOC and the DPF are honeycomb ceramic filters.

However, unlike the DOC, the DPF is a wall-flow filter that traps any remaining soot that the DOC couldn’t oxidize. The soot remains in the DPF until it is regenerated either passively or actively. Passive regeneration occurs when the vehicle’s normal operating temperatures and the DPF will oxidise the particulates anywhere between 275-360⁰ Celsius.

Active regeneration is instigated when sensors detect an excessive build-up of particulates within the DPF. Raw fuel is injected into the exhaust stream to trigger temperatures over 600⁰ Celsius is required oxidise the build-up of soot.

Back pressure usually returns to normal after the soot is gone, however, don’t forget about the ash! Ash builds up inside the DPF and does not burn or oxidize like soot and will remain until removed.

Ash is made of minerals, metals and other trace elements from the breakdown of lubricants, additives and engine wear.

Ash builds up at a much slower rate than soot but if ignored will eventually cause increased back pressure, fuel consumption and sometimes DPF failure. As ash builds inside the DPF the number of active regenerations increase causing poor fuel economy, extreme high temperatures, and more constant back pressure that can be detrimental to the turbo charger.

The longer the ash is left inside the DPF the greater the chance of it hardening into a plug which closes off a portion of the filter.

A vehicle operator will be the first to notice the shorter intervals between regenerations which is the first clue to ash build up and the need to remove the DPF for cleaning. This can also be observed by datalogging the regen cycles in the workshop with diagnostic equipment. When the DPF is removed for cleaning it is always a good practice to also remove the DOC and clean it as well if necessary.

The last component in the after treatment system is a flow through SCR catalyst which introduces Diesel Emissions Fluid (DEF) to the process. This fluid contributes to the further break down of nitrogen oxides that pass through to the SCR filter. Typically the SCR filter doesn’t need maintenance except in rare events where a component related to the DEF fluid fails.

Core Contents

At the heart of these components is an ultra-fine filter in which to capture microscopic particulates. A DOC can contain more precious metals than a DPF and metals such as platinum bonds with the oxygen molecules in hydrocarbons.

A DPF’s core can be made of a few different materials but the most common are cordierite composites. An SCR catalyst has valuable filter contents in the form of ceramic materials and precious metals.

All these filters contain a specific recipe of metals selected for their role in the chemical reactions necessary to effectively clean the emissions. In addition, they are manufactured with materials to resist the higher temperatures of an active regeneration cycle.

Unfortunately the core materials of these filters have made them the target of thefts, especially on vehicles with high ground clearance like people carriers, vans, and trucks.