The knowlage about the Cuimmins SCR aftertreatment system

With the increasingly stringent emission regulations and people’s understanding of post-treatment emission products, customers expect their commercial vehicles to adopt systems with reliable operation, good product performance and fuel economy. At present, the competition trend between the two major domestic manufacturers of SCR post-treatment system is becoming more and more obvious. Cummins and Bosch can provide mature emission treatment solutions to provide customers with more green choices. Let’s introduce the product characteristics of these two brands.

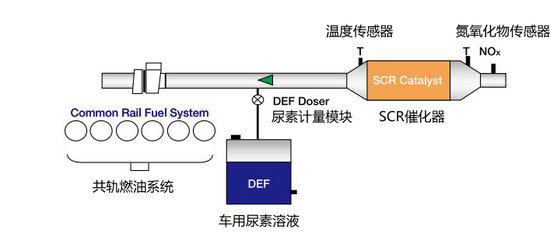

When the common rail system is injected into the combustion chamber, the waste gas generated after combustion enters the exhaust system, SCR uses the urea injection system to inject the urea aqueous solution into the exhaust system, decomposes it into ammonia in the waste gas flow, and reacts with nitrogen oxides under the action of catalyst to convert it into harmless nitrogen and water. The system also uses NOx sensor to detect whether the tail gas meets the emission standard before tail gas emission. Since SCR technology requires higher engine combustion temperature, it is necessary to use temperature sensor in front of catalyst.

Cummins makes the engine perfectly integrated with aftertreatment

SCR system consists of four modules: engine emission control module, OBD on-board diagnostic module, vehicle urea injection module and SCR catalyst module. Some key parts of SCR system related to urea injection system are listed here.