DPF Operation & Regeneration

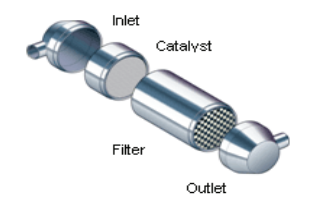

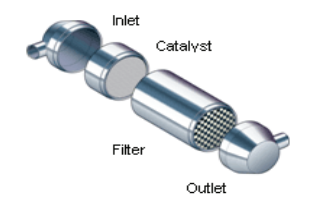

Diesel-Particulate-Filter-DPF

DPF Operation & Regeneration

DPF Operation

DPFs work by physically trapping and removing particulate matter (PM) from the engine’s exhaust. The DPF can accumulate and combust PM within the filter element to achieve greater than 85 percent reductions in PM emissions. The combustion of PM in a filter occurs during regeneration. During normal operation a DPF will cause fluctuations in exhaust backpressure as PM is accumulated. Consequently, a DPF is used in conjunction with an exhaust backpressure monitoring system.

Diesel-Particulate-Filter-DPF

Backpressure Monitoring

As a DPF collects PM, the passage of exhaust gas through the pores of the filter element may be progressively blocked, causing an increase in exhaust backpressure. Collected PM is combusted and reduced to ash during

filter regeneration, effectively unblocking the pores of the filer element and decreasing exhaust backpressure.Normal filter operation will include fluctuations in exhaust backpressure; however, over time the accumulation of ash will gradually continue to increase backpressure. Long term buildup of ash is remedied by periodic filter cleaning.

Engine manufacturers place limits on the exhaust backpressures for their engines; therefore, an exhaust

backpressure monitoring and operator notification system must be installed with every DPF. If exhaust backpressure exceeds certain thresholds, the operator is notified that maintenance is needed. It is important that all vehicle/ equipment operators and fleet service technicians are properly trained to recognize and respond to high backpressure alert signals. Backpressure monitoring systems should be periodically inspected for proper

operation.

Filter Regeneration

Regeneration occurs when the filter element reaches the temperature required for the combustion of the accumulated PM, converting it primarily to ash, gaseous carbon dioxide (CO2) and water (H2O). “Passive” regeneration occurs when the exhaust gas temperatures are high enough to initiate combustion of the accumulated PM in the DPF, without added fuel, heat or driver action. “Active” regeneration may require driver action and/or other sources of fuel or heat to raise the DPF temperature sufficiently to combust accumulated PM. Active regeneration can be accomplished either during normal vehicle operation or during a controlled event while the vehicle is stationary. During operation, active regeneration may use extra fuel to raise the DPF temperature to combust accumulated PM. An active system that requires the vehicle to remain stationary dictates the time required every shift or every day that the vehicle must be out of service. The frequency of regeneration is determined by the engine’s duty cycle, PM emission rate, filter technology, and other factors. When using an active filter, it is particularly important to follow the manufacturer’s instructions for regeneration.