UL2 Urea dosing system-supply unit & dosing unit-part one

Cummins Emission Solutions is a leading global aftertreatment and engineered-component supplier that provides the highest level of technology to support and meet the constantly evolving emissions standards for the on- and off-highway transportation markets. Cummins Emission Solutions offers a variety of proven solutions to best fit your needs, from fully integrated aftertreatment systems to individual system components.

Cummins Emission Solutions newest product addition to its urea doser portfolio is the UL2 Urea Dosing System. This liquid-only dosing system helps reduce oxides of nitrogen (NOx) in both low-flow and highflow Selective Catalytic Reduction (SCR) systems.

The UL2 system is the only liquid-only dosing system commercially available that is capable of meeting highflow dosing rates of up to 20.5 kg/hr.

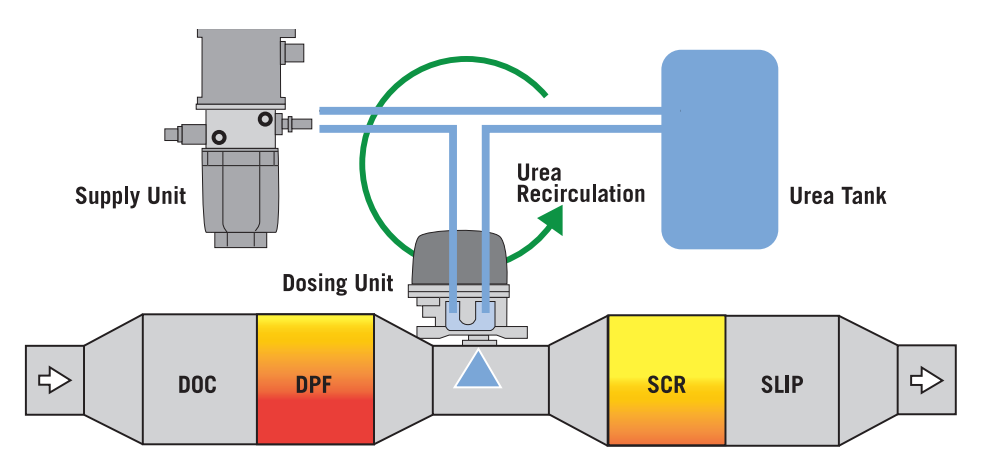

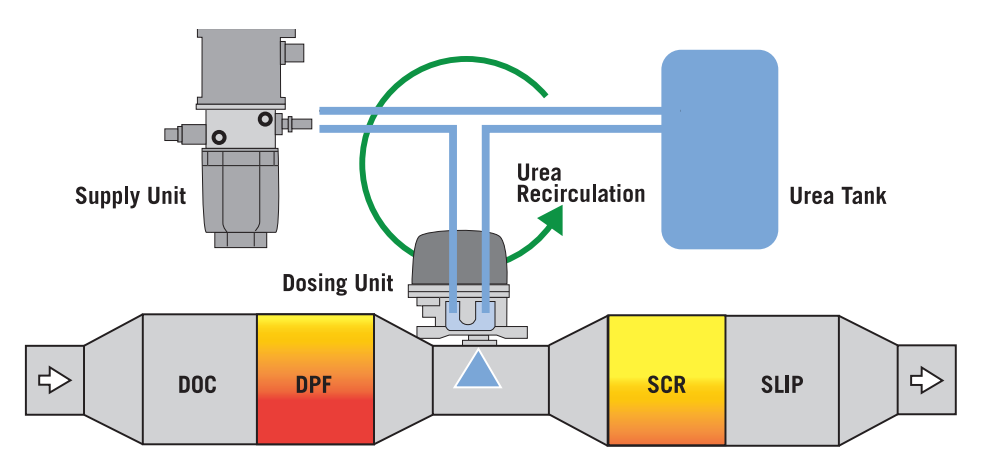

Supply Unit.

– Mounts to the chassis

– Heated by engine coolant

– Enhanced freeze-resistant components

– Contains optional integrated dosing controls to monitor injector, temperature and pressure sensors

Dosing Unit.

– Mounts to the decomposition reactor

– Cooled by urea recirculation; heated by electricity

– Contains a proprietary pressure-swirl atomizer with a reinforced 11-layer nozzle

– Enhanced freeze-resistant components

– Contains injector, temperature and pressure sensors

Flexibility And Ease Of Integration.

The UL2 system has a unique fluid recirculation system that allows the injector to be cooled by urea. Our system maintains its specified temperature range by using a cooler medium instead of traditional methods that use engine coolant. The benefits of this

unique design include:

– Elimination of two cooling lines to the dosing unit, and the addition of only one urea line, reducing complexity of integration

– Optional circulated urea at key-off to counteract heat soak from the exhaust system, improving system reliability

– Automatic depressurization at system shutdown, adding proven reliability in freeze resistance

The UL2 system can accommodate varying dosing line lengths, allowing the distance between the supply and dosing unit to be chosen more freely, without affecting controls technology. The benefits of this modular design include:

– Extended urea transfer line lengths of up to 15 meters, with no extra adaptation of the application parameters required

– The ability to apply dosing units in multiples for high-horsepower engine applications.

Furthering this system’s flexibility in vehicle integration, the supply unit has the option of controls technology via the electronic dosing unit. This technology offers the following built-in capabilities:

– Supply unit pump control

– Dosing unit injector control

– Heating control

– Pressure and temperature sensor controls

– Diagnostic and handling controls

– Heating element control

More urea dosing pump plz click:

Bosch 2.2 urea dosing pump 2871880/A028Y793

or visit our website: www.sukorun.com