DPF and Engine Maintenance

DPF and Engine Maintenance

DPF Maintenance

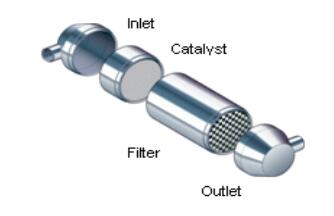

In addition to PM, the filter can also capture non combustible materials mainly produced by lubricating oil and fuel additives (ash). The ash in the modified DPF usually needs to be cleaned every 6 to 12 months. Excessive PM emissions from the engine or insufficient regeneration will cause the DPF to require more frequent cleaning. Diagnostics should be performed to determine the cause of more frequent cleaning intervals. It is important to avoid excessive PM and ash accumulation in the DPF, so proper maintenance and cleaning instructions should be strictly followed. The back pressure monitoring system should always be used with DPF, and the monitoring system should be checked regularly to confirm its normal operation. In general, cleaning requires heating the filter and using compressed air combined with a vacuum system to blow dust out of the filter and collect it in a sealed container. Cleaning requires the DPF to be manually removed from the vehicle and placed in a specially designed cleaning station. Highly automated cleaning stations are emerging, enabling fleet service technicians to clean on site. It also provides professional filter cleaning services. When purchasing DPF, the cost of cleaning station or professional cleaning service should be considered. If equipment downtime is an issue during cleaning, the fleet may consider purchasing additional filters during cleaning. The filter must be reinstalled in the correct flow direction in order to maintain normal operation. Removing the DPF for filter cleaning and reinstallation is usually performed by fleet maintenance technicians. It is important that all vehicle / equipment operators and fleet service technicians are properly trained in filter cleaning procedures. The document shall be kept in the vehicle and / or fleet record, which lists the installation and vehicle information, such as mileage, opacity reading, date, equipment model, DPF serial number, installer, etc. Records should also be maintained to record when repairs are made and when DPF is cleaned. If the fleet moves the DPF between different vehicles, the records should be carefully monitored to determine whether different maintenance intervals are required for specific vehicles or equipment.

Engine Maintenance

It is important to properly maintain the vehicle and monitor fuel and lubricant consumption. The DPF may mask injector damage or increased fuel consumption. DPF may be damaged due to improper engine maintenance. When removing the DPF for cleaning, it may be useful to check the opacity of the vehicle to determine if there are potential engine problems. It is recommended to maintain maintenance records to track potential problems or changes in operation.

Article reference 《Diesel Particulate Filter Operation and Maintenance》