Consolidated Hydrogen fuel cell development planning Cummins Hydrogen Energy China headquarters products into the production stage

Since the signing of the investment agreement on the landing of Cummins Hydrogen Energy China headquarters in Port in September 2021, Cummins has actively linked up the upstream and downstream industrial chains to explore cooperation opportunities. On September 28, 2022, at the “Hydrogen” City meeting event of Lingang New Area Administrative Committee, Cummins and partners in the hydrogen energy field gathered together to witness the release of the hydrogen fuel cell vehicle industry development plan.

As Jing Shuai, general manager of Cummins New Energy and Power Business Division in China, said, “As a world-class free trade zone, Lingang has a grand blueprint for hydrogen industry and a robust hydrogen energy industry chain, providing a strong and dynamic environment for enterprises to accelerate their development. Cummins is honored to land the dual headquarters of Hydrogen Energy China and Hydrogen Energy China R&D Center in Lingang. We will link up with the upstream and downstream enterprises in Lingang industry chain to fulfill our commitment to the decarbonization goal, and make a positive contribution to the goal of carbon peak and carbon neutrality.”

See “hydrogen” core strong power safe and reliable

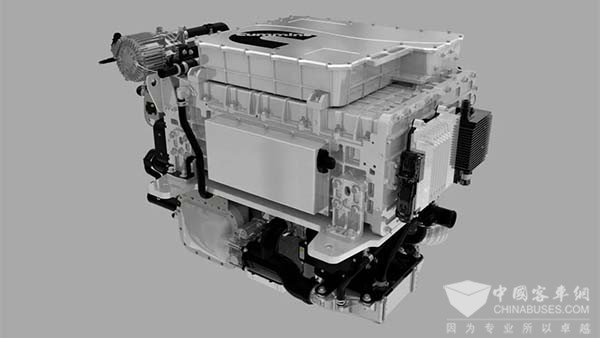

Cummins continues to innovate actively in zero-emission power. Relying on the perfect hydrogen energy ecosystem in Lingang, Cummins has cooperated with outstanding local upstream and downstream parts enterprises to create a rich product matrix and provide power for a variety of application scenarios, including buses, urban slag trucks, heavy trucks, power generation and other fields. The Cummins HD120 fuel cell product developed by Lingang and produced by Lingang has officially entered the production stage. The product is being developed jointly with the main engine factory and customized and optimized for bus application scenarios. It has the characteristics of high power, high efficiency, low hydrogen consumption, safety and reliability.

Cummins HD120 fuel cell product features

The rated net power of 1.125kW can effectively meet the full power operation of the bus, and the power density of the reactor is up to 3.5kW/L.

2. Peak efficiency of the engine can reach 60%, rated power point efficiency of 42%. Cooperate with the energy management control strategy of the OAR factory, the hydrogen consumption of 100km under full load is less than 5kg, leading the peer by more than 5%.

3. With rich experience in hydrogen energy and international leading technical standards to assist the vehicle hydrogen-related safety guarantee, in the whole vehicle and power system insulation design, hydrogen system safety monitoring, emergency safety disposal and other aspects of joint optimization.

4. Cummins hydrogen energy is an exclusive smart big data tool, which can jointly carry out hydrogen consumption management, driving behavior analysis, hydrogen energy safety management, etc. with end customers, and escort the whole life cycle of vehicles through active intelligent services.

In addition, we inherit Cummins century-old design verification and quality management system to ensure more stable and durable products. Cummins and VIentiane have completed a total of 8,000 kilometers of strict road test (the road test is strengthened in the whole process, with a load strength of 6.5 tons, equivalent to the actual driving distance of 80,000 kilometers) and 2,500 hours of DVPR endurance test to ensure that the reliability and durability of the products are fully verified.

Fully cooperate with Lingang hydrogen energy industry base to participate in and cultivate the hydrogen energy ecosystem

In September 2021, Cummins New Energy Power China double headquarters will be launched in Shanghai Lingang New area. The first phase of the project will be put into operation by the end of 2023, with the manufacturing capacity of 5000 fuel cells and 500 MW power reactors, and the subsequent capacity can be expanded to 1GW. It covers the business of electric reactor, fuel cell engine and its core parts, high pressure hydrogen storage bottle system and so on.

Learning from the localization experience of Cummins’ cornerstone business in China for more than 40 years, Cummins Hydrogen Energy China adheres to the localization and long-term strategy to build the capacity of the whole industrial chain of production, research and development, distribution, service and supply chain of new energy power business in China, and jointly promote the development and breakthrough of hydrogen energy industry with industry partners.

New energy has been put into use of cummins power Shanghai temporary production line, covers an area of 4000 square meters, factory according to international manufacturing standard and cummins, involving hydrogen safety standards for construction, equipped with water electrolysis hydrogen production equipment laboratory, fuel cell test system, quality checkout room, between the fuel cell engine assembly, and related laboratory involved hydrogen, It has complete testing, testing and manufacturing capabilities for hydrogen products. In addition, the fuel cell engine test bench that has been put into use adopts modular design to realize high-precision control and real-time monitoring of product performance.

The whole industrial value chain of system, storage, transportation and use is developing in synergy

The batch landing of Cummins hydrogen energy project in Lingang will prospectively promote the progress of hydrogen energy technology and the coordinated development of the whole industrial chain. Cummins is rapid development of new energy power business, inner world and hydrogen fuel cells technology has carried on the profound technology accumulation, through active layout and development of hydrogen technology capabilities, providing customers with “system of storage and transportation and use” the whole industrial chain system solutions, including design and production of proton exchange membrane and solid oxide fuel cell system and core components, And high pressure hydrogen storage system, water electrolysis hydrogen production equipment, megawatt hydrogen energy and multiple energy coupling solutions, together with the whole industrial chain value partners to make breakthroughs in hydrogen energy commercial innovation.