The adjustment method for the gasket of the diesel electronic injection common rail injector is here, please do not repair it like this again

Fuel injector type:

There are two types of fuel injectors: open and closed. Nowadays, diesel engines generally use closed fuel injectors, which are divided into two types: hole type fuel injectors and needle type fuel injectors.

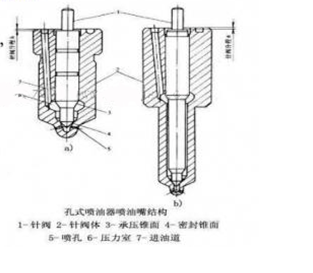

(1) Orifice type fuel injector:

The hole type fuel injector mainly consists of needle valve components, top rod, pressure regulating spring, pressure regulating screw, and fuel injector body. The orifice type fuel injector is used on direct injection combustion chamber diesel engines.

Working principle: The high-pressure diesel output from the fuel injection pump enters the high-pressure oil chamber in the middle of the needle valve through the inlet pipe joint. When the oil pressure overcomes the pre tightening force of the pressure regulating spring and the friction between the needle valve components, the needle valve rises and high-pressure diesel is sprayed out from the injection hole. When the fuel injection pump stops supplying oil, the needle valve closes the injection hole under the action of the pressure regulating spring.

(2) Needle type fuel injector:

The needle type fuel injector is mainly used for separated combustion chamber diesel engines.The working principle is the same as that of a hole type fuel injector.

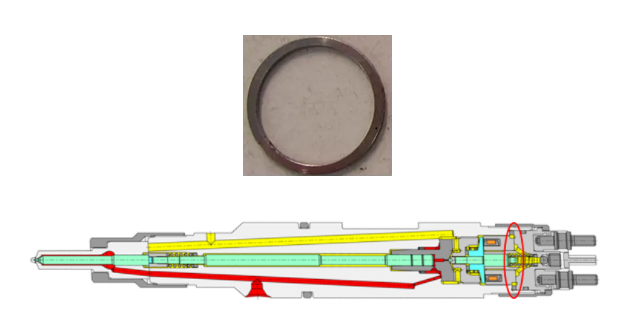

The armature lift gasket is a large circular gasket used to adjust the magnitude of the armature lift.

The lift of the armature refers to the distance the armature moves upwards, used to adjust the maximum displacement of the ball valve’s up and down movement. The set values range from 40 microns to 60 microns, and most CRIN2 fuel injectors in the Chinese market are 52 microns or 55 microns, with a maximum allowable tolerance of ± 5 microns.

The larger the lift of the armature, the higher the corresponding needle valve is lifted, resulting in a higher fuel injection rate. For CRIN injectors, within the normal deviation of the set value, the impact on the fuel injection rate at other injection points is not significant, only the impact on pre injection is relatively large.

As the armature lift gasket is located between the fuel injector housing and the solenoid valve, the thicker the armature lift gasket, the greater the armature lift, and the greater the pre injection amount.