What we can do as we meet Severing blockage of DPF caused by abnormal regeneration

If there are frequent DPF severe blockage faults (regeneration indicator light flashing/red regeneration indicator light illuminated or carbon load indicator light already illuminated as a serious carbon accumulation state, different manufacturers), the carbon load and pressure difference are very high at this time, indicating that DPF regeneration cannot proceed normally. First, investigate whether active regeneration mode can be entered:

1) Use diagnostic equipment to read faults and confirm if there are relevant fault codes that prevent active regeneration.

(2) Inquire about the actual operating conditions of the vehicle, understand whether the temperature upstream of the DOC can rise above 250 ℃ during vehicle operation, and obtain information on the vehicle’s operating conditions (vehicle speed, load), environmental temperature, and distance traveled each time.

(3) Understand whether the driver has performed a parking regeneration after the DPF indicator light is activated. If the regeneration operation is not taken even after the indicator light is turned on, it can cause serious blockage of the DPF.

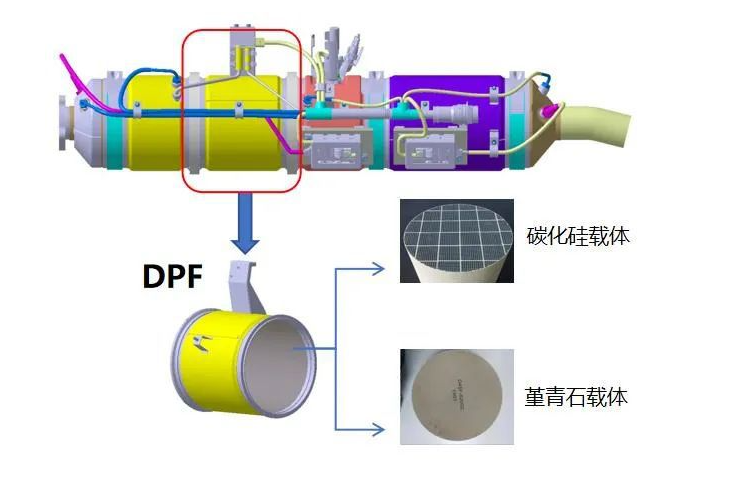

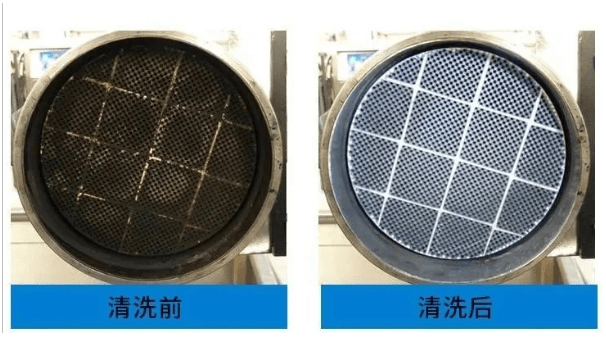

(4) After severe blockage of the DPF, it is necessary to remove the DPF for ash cleaning. After ash cleaning, a parking regeneration test function is conducted to check whether the temperature before DOC can reach 250 degrees Celsius or above. If the DOC temperature cannot be raised, it will cause regeneration to fail. Please check whether the exhaust temperature sensor data is reasonable and whether there is a malfunction in the intake throttle valve.

(5) If the DOC temperature can increase to 250 degrees Celsius or above after parking regeneration, it indicates that the first heating of the regeneration is completed and enters the second heating stage. At this time, it is necessary to observe the DPF temperature. Under normal conditions, the DPF temperature should quickly rise to 600 ± 50 ℃. At this point, the regeneration has been activated normally. If the DPF temperature is significantly low or fluctuates greatly, it is necessary to check:

① Check the upstream and downstream pressure status, upstream temperature, and whether the nozzle of the hydrocarbon injection system is spraying well and atomizing normally;

② Check if there is any leakage in the exhaust pipe. The exhaust pipe of National VI should be well insulated;

③ Check if the exhaust temperature sensor is faulty;

If there are no issues with the above checks, it is necessary to check whether the DOC is invalid;

The conditions that trigger active regeneration include: carbon load, driving distance, driving time, and fuel consumption. In the calibration strategy, the quality detection value of carbon smoke particles is used as the priority for determining regeneration needs, while other regeneration needs (such as driving distance, driving time, etc.) are determined based on the manufacturer’s priority calibration of regeneration needs.