Electric mobility transformation speed up! Zf new energy electric drive motor production exceeded 3 million units

Recently, the production of ZF motors has exceeded the 3 million mark, and the technology is widely used in various types of electric vehicles worldwide. The solutions offered by ZF cover a wide range of areas from pure electric and plug-in hybrid passenger vehicles to the electrification of commercial vehicles. As an important milestone, the mass production of more than 3 million motors shows the market’s decreasing reliance on pure fuel engines and marks the successful transition of the entire industry towards electric mobility.

Globally, the demand for electric drives in electric passenger cars and commercial vehicles is growing rapidly, and ZF production is also increasing rapidly. Roland Hintringer, Head of the ZF Group’s global motor technology and transmission components product line, said: “ZF’s motor production has soared to 3 million, thanks to a highly automated, flexible and modular production system that allows us to provide service and technical support to customers around the world on demand.”

Improve efficiency and range through iterative innovation

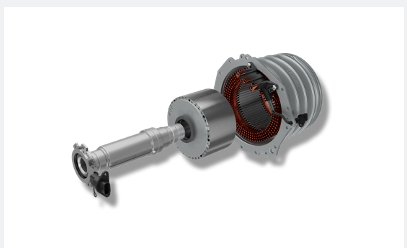

Zf’s production figures and forecasts clearly show that the company has successfully driven the transition to electric mobility. “Zf plays a crucial role as an innovator in the transformation process,” stressed Roland Hintringer. Zf has announced the mass production of its newly developed in-shaft induction exciting synchronous motor (I²SM), a compact synchronous motor that transmits magnetic field energy through an in-rotor induction exciter. Unlike the magnetically free concepts on the market today, this motor achieves maximum power and torque density. Zf recently demonstrated the potential of this new technology to improve the efficiency and range of electric mobility with the EVSys800 electric drive system, a modular 800-volt drive system that is 35% lighter than the current mainstream 800-volt drive system and reduces CO2 emissions in production and operation by 20%. At the same time, the system’s innovative braided winding technology, new in-tank cooling scheme and ultra-compact overall design further enhance the overall performance of the electric drive system.

Global production base

In Asia and Europe, ZF has set up a number of motor production sites; In North America, new production facilities are also in the pipeline. With production sites in many cities and regions around the world, including Hangzhou and Shenyang in China, Pancevo in Serbia, Schweinfurt in Germany, Ternava in Slovakia, Saltillo in Mexico, and Gecot in the United States, ZF is providing a full range of services to the major automotive markets. In order to best support our customers’ ambitions in sustainability and environmental protection, ZF will continue to expand existing production facilities and site capacity, combined with technological innovation to improve motor performance to the end.