Who monitors and calculates the SCR conversion rate

1. Monitoring of SCR conversion efficiency:

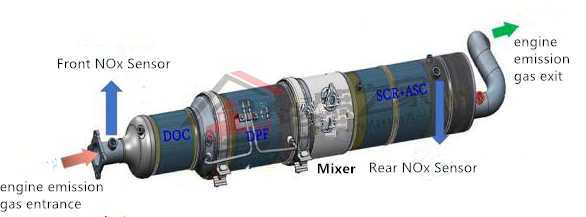

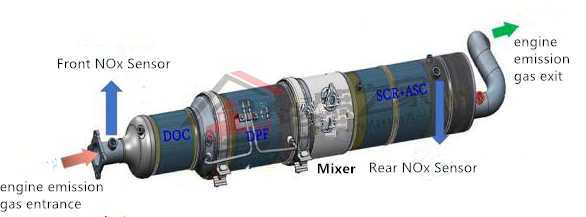

In the post-treatment system of National VI, there are a total of 2 nitrogen oxygen sensors, and the front nitrogen oxygen sensor is installed between the turbocharger exhaust outlet and the DOC (oxidation catalyst) pipeline connection.

Front nitrogen and oxygen sensor: measures the nitrogen and oxygen concentration before SCR. Compared with the National V stage, the original exhaust replaces the model value and transmits the corresponding signal to the ECU for controlling the urea injection amount。

The rear nitrogen oxygen sensor is installed at the end of the exhaust pipeline to measure the NOx concentration after SCR for OBD monitoring, monitor the conversion efficiency of post-treatment, and achieve closed-loop control of urea injection.

The application of two nitrogen oxygen sensors can achieve closed-loop control of urea injection, accurately controlling the amount of urea injection.

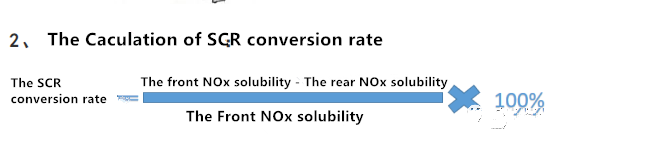

The data flow of the diagnostic instrument can read the values of upstream/downstream nitrogen and oxygen concentrations, and the conversion efficiency of SCR can be obtained through the above calculation (preferably monitoring the conversion efficiency at the stage when urea injection begins after driving for more than 20 minutes).

In the sixth stage of China, most manufacturers require the overall conversion efficiency of SCR to be greater than 90% (some manufacturers require a higher conversion efficiency of up to 99%).