DPF regeneration control strategy

一、DPF control principle

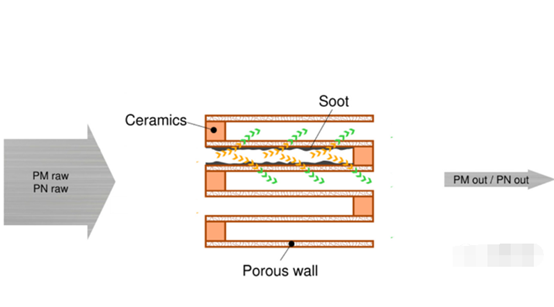

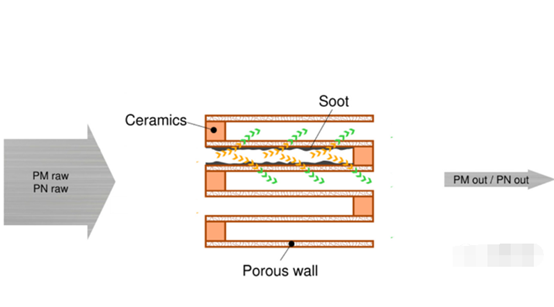

The DPF system has two functions: particle capture and particle regeneration. Diesel engine exhaust air enters from the channel plugged at the bottom of the DPF, and can only flow from the micro-hole on the wall of the channel to the adjacent channel plugged at the front. Particulate matter is filtered down by the channel wall, which is called the trap function of DPF, which does not require ECU intervention control. DPF regeneration is the process of removing carbon smoke from the DPF, mainly to prevent the risk of excessive back pressure or even clogging of the DPF system.

二、there are three DPF regeneration modes:

Passive regeneration: when the vehicle is running normally, the exhaust thermal management system controls the pre-DOC exhaust temperature above 250℃, DOC converts NO into NO2, and in the DPF, NO2 reacts with carbon to produce CO2 for passive regeneration. The heat provided by the exhaust thermal management is sufficient to fully regenerate the DPF.

Active regeneration:

- a) Active regeneration 1: The working environment temperature of the vehicle is low, the average speed of long-term driving is lower than 15km/h, and the passive regeneration fails. During the driving process of the vehicle, the system automatically triggers the active regeneration, and the exhaust thermal management system will raise the DPF inlet temperature to more than 550℃, burning the carbon smoke accumulated in the DPF, and the DPF can achieve rapid regeneration. The engine controller takes power compensation measures during the regeneration process, and the driver does not feel the regeneration.

- b) Active regeneration 2 (parking regeneration) : When the above two modes are not enough to complete the DPF regeneration due to unexpected circumstances, the DPF status indicator is lit, prompting the driver to perform DPF parking (manual) regeneration. The driver stops the vehicle on the side of the road, presses the manual regeneration button, the post-processing control system will automatically increase the engine idle speed, the exhaust thermal management system will increase the exhaust temperature to more than 550 ° C, burn the carbon smoke inside the DPF, and complete the regeneration in about 30 minutes.

Service regeneration: Due to uncontrollable circumstances, when the above control mode is not enough to complete the regeneration of DPF, maintenance measures such as ash cleaning and carbon cleaning must be carried out by maintenance personnel.

三、DPF regeneration control principle

The conditions that trigger active regeneration are carbon load, mileage, driving time and fuel consumption. In the calibration strategy, the carbon smoke particle quality detection value is used as the priority to determine the regeneration demand, and other regeneration needs (such as mileage, driving time, fuel consumption, etc.) are prioritized according to the regeneration demand.

In regenerative mode, the relevant Settings of the engine will be greatly changed compared to the normal mode. By changing the main injection timing, rail pressure, throttle, EGR, near rear injection and other methods to increase the engine exhaust temperature, and finally ensure that the DPF inlet T5 temperature above 550℃, in order to achieve efficient regeneration process. At the same time, in order to ensure the driving experience in regenerative mode, the relevant performance calibration strategies in different mode switching processes are also targeted to optimize, in order to minimize the subjective impact of regeneration on drivers.