The Structure and Maintenance Guidelines for National VI Or Euro VI Aftertreatment Systems

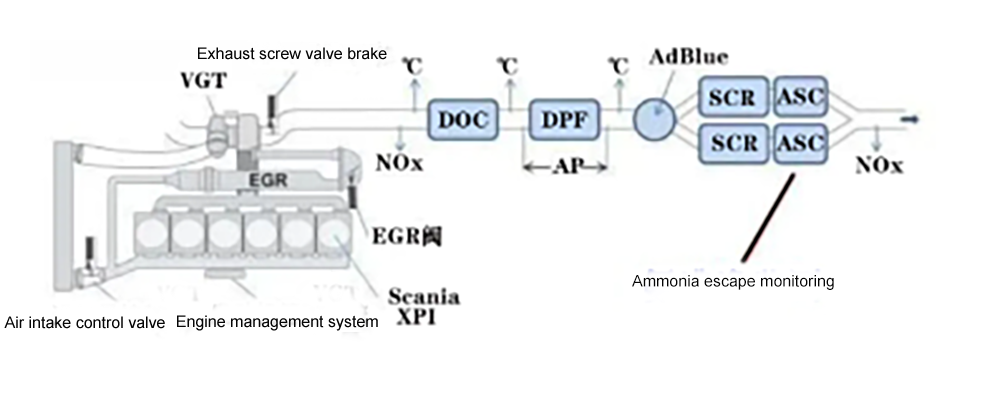

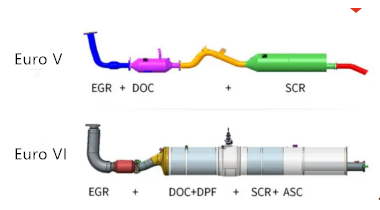

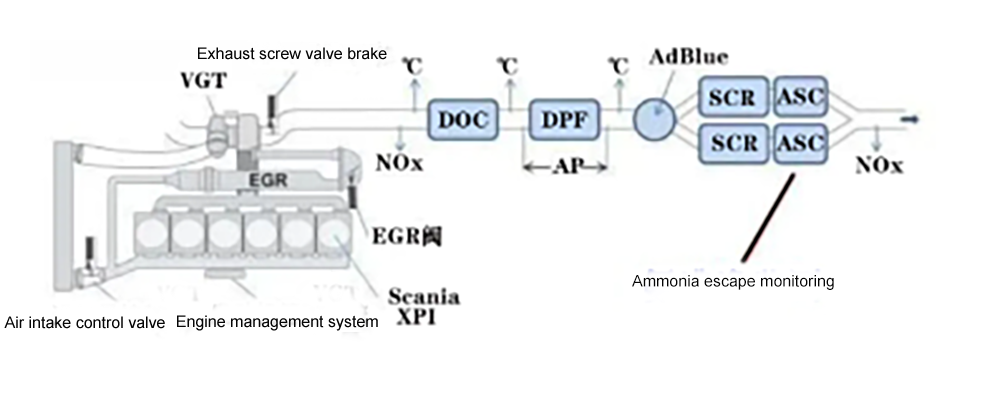

From the above two figures, it can be seen that the post-processing system of National V has SCR, while the post-processing system of National VI has ASC, DPF, and DOC in addition to SCR.

Next, the editor will explain to you the four major devices of the National VI post-processing system.

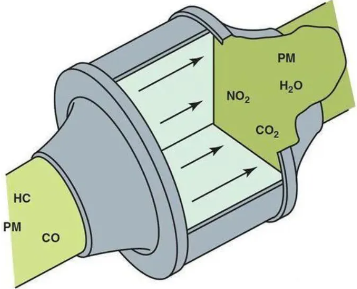

The First Step: DOC

The main objects of DOC post-processing are hydrocarbons and carbon monoxide, both of which are harmful to the human body.DOC will oxidize toxic gases entering the DOC through devices that provide oxygen, generating water and carbon dioxide inside the DOC. The current mainstream DOC system mainly consists of a carrier and a catalyst, and there is also a sensor at the back end of the DOC to monitor its working status. At present, the conversion efficiency of DOC can usually reach over 60%.

https://www.sukorun.com/product/diesel-oxidation-catalyst-doc/

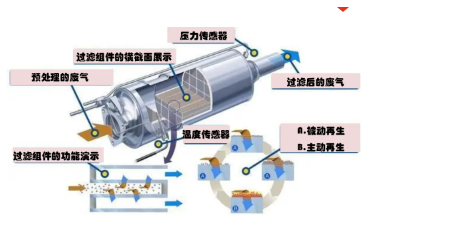

The Second Step: DPF

DPF is relatively easy to understand. It removes black smoke (dry carbon smoke) from the exhaust gas, and most of the DPF systems only became popular after National VI, so installing this thing in the post-treatment of the exhaust gas will make it appear cleaner. It can effectively purify 70% -90% of particulate matter and is currently the most effective and direct method for tail gas treatment.As a filtering mesh device, DPF will become clogged after a period of use, and the regeneration function of DPF will come into play. This regeneration function is also easy to understand, which is to oxidize (burn) dry carbon smoke to produce carbon dioxide and discharge it through heating.

https://www.sukorun.com/product/diesel-particulate-filter-dpf-euro-6-21716414-21716416-21716417-23135528/

The Second Step: SCR

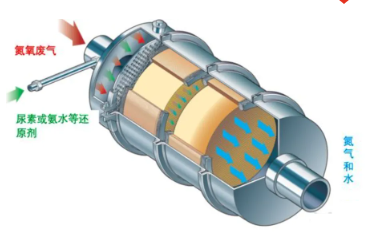

The SCR system is mainly responsible for removing nitrogen oxides that have already been generated in the exhaust gas. Its working principle is relatively complex, requiring not only the cooperation of the urea feeding device, but also real-time communication with the driving computer ECU to determine the feeding amount, which is the most headache inducing thing for car enthusiasts.Intuitively speaking, the SCR work involves the on-board computer first telling the SCR the amount of urea pump to spray, and the urea pump then sprays a certain amount of urea into the front end of the SCR, using the exhaust temperature to decompose into the required ammonia gas. The ammonia gas further reacts with nitrogen oxides to generate harmless nitrogen and water. At present, the conventional SCR system can achieve a conversion rate of over 70% for nitrogen oxides.

https://www.sukorun.com/product/diesel-particulate-filter-dpf-euro-6-21716414-21716416-21716417-23135528/

The Fourth Step: ASC

The ASC system is relatively rare, and the National VI model is also relatively less equipped. It mainly serves as an “SCR supervisor”, responsible for removing excess ammonia from the SCR system reaction to avoid secondary pollution.

In the ASC system, excess ammonia gas in the SCR reaction will continue to react with oxygen to generate nitrogen oxides. At the same time, the generated nitrogen oxides will continue to react with excess ammonia gas to generate harmless nitrogen gas for discharge. It is a device taken from SCR and used for SCR, which can be said to bring the concept of waste utilization to the extreme.

https://www.sukorun.com/product/customized-volvo-series-euro-vi-national-vi-exhaust-after-treatment-system-with-e226-uds-urea-dosing-pump-for-the-volvo-dongfeng-truck/