DPF (Diesel Particular Filter) maintenance and upkeep methods

How Diesel Fuel Quality Affects Modern Emission After-Treatment Systems

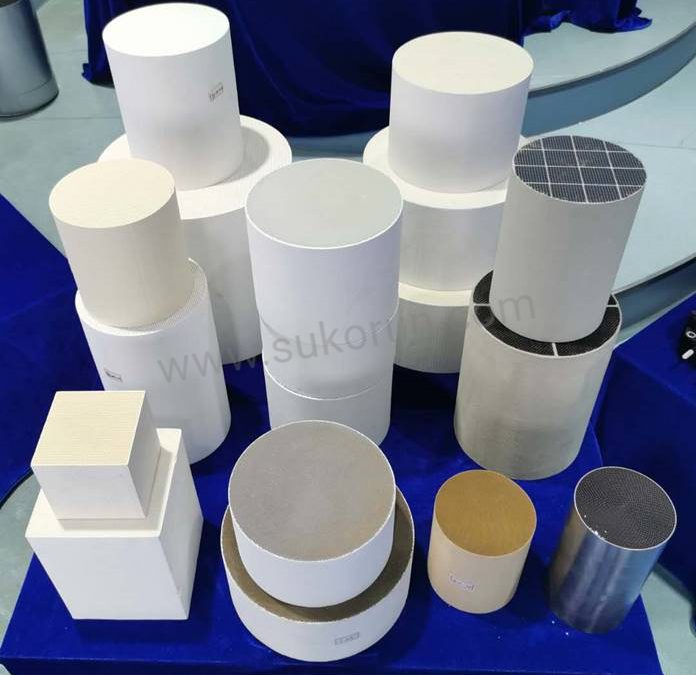

DPF is an important component of our post-processing equipment. Today, we will talk about the daily maintenance and upkeep of DPF products.

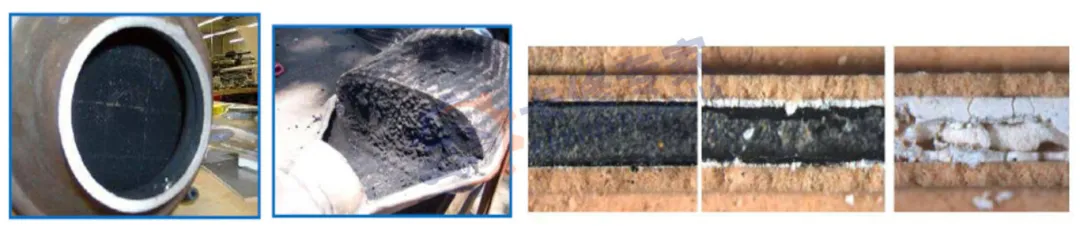

In addition to collecting soot, DPF also collects engine oil, additives, and substances produced by diesel combustion (mostly sulfates, which we call ash). Charcoal smoke can be consumed through passive regeneration or active regeneration, allowing DPF to maintain high capture efficiency throughout its entire lifecycle. However, ash cannot be eliminated through regeneration and accumulates on the inner wall of the DPF. On the one hand, it reduces the effective filtration area of the DPF, thereby affecting its capture efficiency, and on the other hand, it increases the exhaust back pressure。

The maintenance of DPF mainly involves the process of cleaning dust; The components of the control system and HCI injection system are generally maintenance free throughout their lifecycle, but regular inspections and hazard assessments are also necessary. In addition, if there is a malfunction in the DPF system or the active regeneration function of the DPF fails, the carbon deposits in the DPF should be treated according to the cleaning process.

Dust removal method

The DPF particulate trap assembly is cleaned by heating and blowing.

(1) Remove the DPF and weigh its mass.

(2) Heat the DPF particulate trap assembly to a temperature of 600 ± 50 ° C for 20 minutes;

(3) After the heating of the DPF particulate trap assembly is completed, compressed air is used to blow back the DPF particulate trap assembly with a blowing pressure of 13 bar and a blowing time of 20 minutes. When the DPF particulate trap assembly is severely clogged, the blowing time can be extended;

(4) After the DPF heating and blowing are completed, remove the DPF and weigh it.

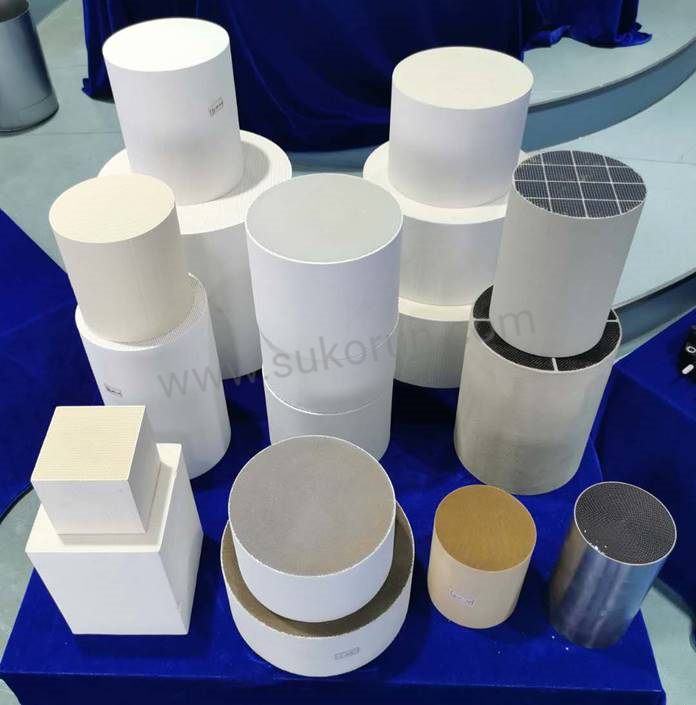

SCR DPF

SCR DPF