The world’s top three diesel system suppliers-common rail fuel system

As the most widely used power machinery in the world, diesel engines play an extremely important role in various industries. There are many diesel engine brands in the world, but as the core fuel injection system of diesel engines, there are only three mature and stable suppliers in the world: Bosch, Denso and Delphi. These three companies have dominated the global diesel engine market at the technical level. Let’s talk about the world’s three largest diesel system suppliers.

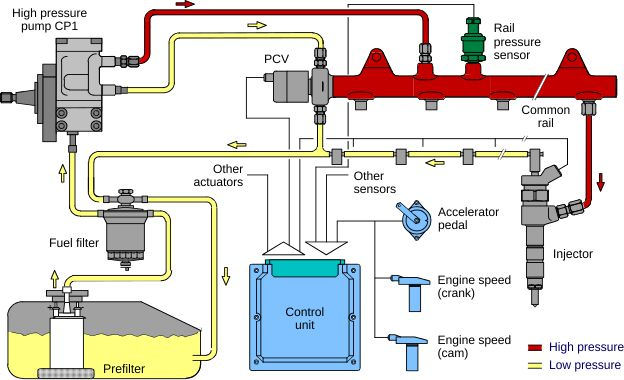

Bosch Fuel System Bosch fuel system is an advanced fuel supply system mainly used for automobile engines. It includes a variety of different technologies and equipment, such as electronic fuel injection system, high-pressure common rail fuel system , etc., designed to improve fuel efficiency, reduce emissions, and improve vehicle performance Bosch’s electronic fuel injection system is an engine electronic gasoline injection system, which is used to detect the working condition of the engine and accurately control the fuel injection amount and injection timing. This system is mainly composed of various sensors, various actuators and controllers (also known as electronic control units ECU). The function of the sensor is to convert physical quantities such as the working condition and state of the engine, the driving condition and state of the car into electrical signals and transmit them to the ECU. The actuator is used to execute various control instructions issued by the engine ECU, mainly including: electric fuel pump, injector, idle speed control (ISC) valve, exhaust gas recirculation (EGR) valve and self-diagnosis system.

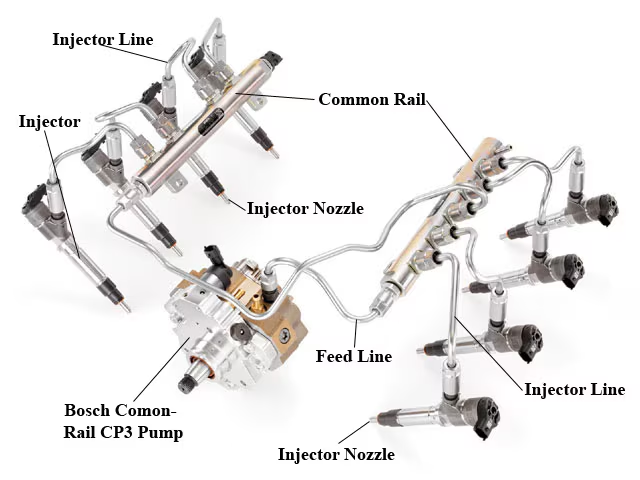

Bosch high-pressure common rail system

In addition, Bosch’s high-pressure common rail system is also an important fuel system technology. This system can provide higher fuel pressure, so that the fuel is better atomized, so that it burns more fully, further improves fuel efficiency, reduces emissions, and enhances power performance. For example, Yuchai Tongji uses a stable and reliable Bosch high-pressure common rail fuel system, and the engine matching this system has good performance.

In general, Bosch fuel system achieves precise control of fuel supply through advanced technology and equipment, which helps to improve the fuel efficiency of the car, reduce emissions, and improve vehicle performance.

The main features of Bosch fuel system include:

- Precise control: Bosch fuel system can accurately control the injection amount and injection timing of fuel according to the working condition of the engine and the driving condition of the car, thereby improving fuel efficiency, reducing emissions, and improving vehicle performance.

- High-pressure common rail technology: Bosch fuel system uses high-pressure common rail technology, which can provide higher fuel pressure, make the fuel better atomized, so as to burn more fully, further improve fuel efficiency, reduce emissions, and enhance power performance.

- Modular design: Bosch’s new generation of oil pump CP4 adopts modular design, which has the characteristics of light weight and high pumping efficiency.

- Strong adaptability: Bosch fuel system can flexibly control injection pressure and oil volume according to different working conditions of the engine, and achieve low speed high torque, low emissions and efficient fuel utilization.

- High reliability: Bosch fuel system uses high-quality components and strict quality control to ensure the reliability and stability of the system.

- Environmental protection: Bosch fuel system can effectively reduce exhaust emissions by precisely controlling fuel injection, which meets the current environmental protection requirements.

The above are some of the main features of Bosch fuel system. Its design and manufacturing reflect Bosch’s in-depth understanding and continuous innovation of fuel system technology.

Denso diesel injection system

The Denso diesel injection system is an advanced fuel supply system that precisely controls the injection of fuel through an electronic control unit (ECU). The main advantage of this system is that it can provide a more uniform and accurate fuel supply, thereby improving combustion efficiency and reducing emissions.

The basic components of the Denso diesel injection system include: high-pressure pump, high-pressure pipeline, fuel injector, electronic control unit (ECU) and sensors. Among them, the high-pressure pump is responsible for compressing the fuel to high pressure and then delivering it to each fuel injector through the high-pressure pipeline; the fuel injector is responsible for spraying the fuel into the combustion chamber in the form of atomization; and the electronic control unit (ECU) calculates the optimal fuel injection time and injection amount based on the sensor signal, and then sends instructions to the high-pressure pump and fuel injector

The working principle of the Denso diesel injection system is as follows: When the engine is started or running, the electronic control unit (ECU) will receive signals from various sensors, such as crankshaft position sensor, cylinder pressure sensor, intake volume sensor, etc. These signals will be processed by the ECU and converted into fuel injection commands, and then transmitted to the high-pressure pump and fuel injector through the drive circuit. After receiving the command, the high-pressure pump will compress the fuel to high pressure, and then deliver it to each injector through the high-pressure pipeline. Finally, after receiving the command, the injector will spray the fuel into the combustion chamber in the form of atomization, mix with air and burn to generate power.

The advantages of the Denso diesel injection system are mainly as follows: First, since the injection time and injection amount of the fuel can be precisely controlled, more efficient and cleaner combustion can be achieved, thereby improving the performance and fuel economy of the engine; second, due to the use of electronic control, more complex fuel management strategies can be achieved, further improving the performance and environmental protection of the engine; finally, due to the reduction of mechanical parts, the failure and maintenance costs can be reduced.

In general, the Denso diesel injection system is an advanced fuel supply system that realizes precise fuel injection through electronic control, thereby improving the performance and environmental protection of the engine.

The Denso diesel injection system is an advanced fuel supply system mainly used in automobile engines. Here are some of its main features:

- Precise control: The Denso diesel injection system can precisely control the injection amount and injection timing of the fuel, thereby improving fuel efficiency, reducing emissions, and improving vehicle performance.

- High-pressure common rail technology: Denso diesel injection system uses high-pressure common rail technology, which can provide higher fuel pressure, make the fuel better atomized, so as to burn more fully, further improve fuel efficiency, reduce emissions, and enhance power performance.

- Modular design: Denso’s new generation of oil pumps adopts a modular design, which is lightweight and has high pumping efficiency1.

- Strong adaptability: Denso diesel injection system can flexibly control injection pressure and oil volume according to different engine working conditions, achieving low speed high torque, low emissions and efficient fuel utilization.

- High reliability: Denso diesel injection system uses high-quality components and strict quality control to ensure the reliability and stability of the system.

- Environmental protection: Denso diesel injection system can effectively reduce exhaust emissions by precisely controlling the injection of fuel, which meets the current environmental protection requirements.

High injection pressure: The diesel common rail system developed by Denso can reach the world’s highest injection pressure of 250MPa, which can not only improve fuel efficiency, but also effectively reduce exhaust emissions.

Delphi Diesel Injection System Introduction

Delphi Diesel Injection System is an advanced fuel injection technology mainly used in diesel engines. The main goal of this system is to optimize fuel economy, reduce emissions and improve engine performance.

Delphi Monomer Pump System

Delphi’s Monomer Pump System is an electronically controlled monomer pump system, which is characterized by integrating the driver into the pump body and can reach an injection pressure of 2000 bar. This system has a programmable injection control system, can guarantee a durability of 1 million kilometers, and is quick to install. In addition, the system also meets the Euro III emission requirements, achieves rapid air and fuel mixing, reduces smoke and particulate emissions, and improves BSFC.

Delphi’s Common Rail System, also known as DCR (Delphi Diesel Common Rail), is a modular design technology suitable for engines of different structures and forms. The system mainly consists of a common high-pressure fuel accumulator (common rail), a high-pressure fuel regulator (optional component), a fuel pump with a built-in high-pressure pump and a fuel metering primary fuel supply pump structure, a fuel injector (injector), an engine electronic control unit (ECU) and a fuel filter.

A key feature of the Delphi common rail system is that its high-pressure fuel pressure is independent of engine speed, which allows the system to provide high-pressure fuel and perform high-pressure fuel injection at very low engine speeds. The system directly drives the electromagnetic switch designed inside the fuel injector through the engine electronic control module to control the opening and closing time and frequency of fuel injection.

Advantages of Delphi Diesel Injection System

The main advantages of the Delphi diesel injection system are its compact structural design and modular system composition. Its main components are exquisitely designed and small in size, which is very suitable for modern two-valve and four-valve engines. In addition, the modular combination structure with an electronically controlled fuel injector per cylinder can be easily applied to any three-cylinder, four-cylinder, five-cylinder and six-cylinder diesel engines.

In general, the Delphi diesel injection system provides an efficient and reliable fuel injection solution that helps improve engine performance and efficiency, while also helping to reduce emissions and meet increasingly stringent environmental regulations.

Features of Delphi Fuel System

Delphi fuel systems are widely recognized for their efficiency and environmental protection. Here are some of the main features:

- Efficiency: Delphi fuel systems use precise fuel injection technology to inject the right amount of fuel into the engine at the right time, thereby improving fuel utilization and engine efficiency.

- Environmental protection: Because Delphi fuel systems can accurately control the amount of fuel injected, they can reduce fuel waste and exhaust emissions, which is beneficial to environmental protection.

- Fuel economy: Delphi Technologies offers a range of proven environmental technologies that can significantly improve fuel economy.

- Engine performance: Delphi fuel systems can improve engine performance and keep it in optimal condition under various working conditions.

- Adaptability: Whether it is diesel, gasoline or electric vehicles, or passenger cars, light commercial vehicles, heavy vehicles or off-road vehicles, Delphi fuel systems can be applied.

- Advancedness: Delphi fuel systems use the latest technology and design, making them a leader in the fuel injection system market.Reliability: Delphi fuel systems have undergone strict quality control and long-term testing to ensure their stability and reliability under various working conditions

The above are some of the main features of Delphi fuel system. Its high efficiency, environmental protection, fuel economy, engine performance, adaptability, advancement and reliability make it the first choice of many automakers.

The above is the introduction of the world’s three major fuel system suppliers. This issue ends here. Please continue to pay attention to more content!

Personal opinion, for reference only