Fuel injectors: from working principles to the development of modern diesel engines

The electronic fuel injector is the core component of the common rail system. The ECU accurately controls the timing and amount of fuel injection. Its extremely high processing precision ensures dynamic flow, anti-clogging and atomization performance. The fuel economy of diesel engines is more than 30% higher than that of gasoline engines, and independent injection timing and pressure control technology further optimizes combustion efficiency.

The processing precision of the fuel injector is extremely high, and it needs to have a wide range of dynamic flow, anti-clogging, anti-pollution capabilities and good atomization performance. The processing precision of this device is extremely high, and it not only needs to have a wide dynamic flow range, but also excellent anti-clogging, anti-pollution capabilities and good atomization performance. The electronic fuel injector is the most critical and difficult component in the common rail system.

In the common rail system, the injector receives the ECU signal and accurately controls the fuel injection to ensure the effective injection start point and injection amount. Through the ECU’s control of the opening and closing of the solenoid valve, the fuel in the high-pressure rail can be injected into the combustion chamber at the best time, with the best injection amount and injection rate.

Working principle of fuel injector

◉ Operational relationship with common rail system

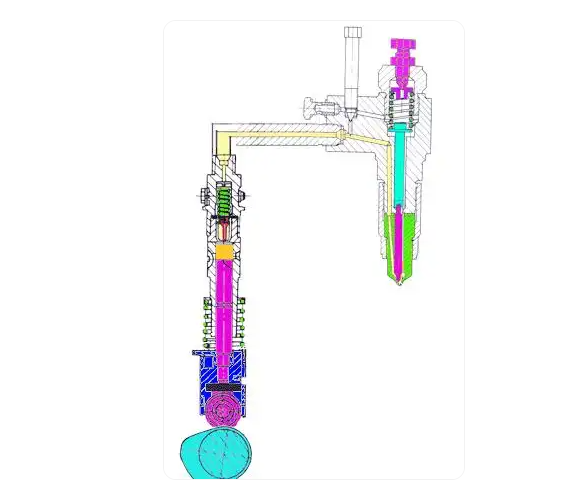

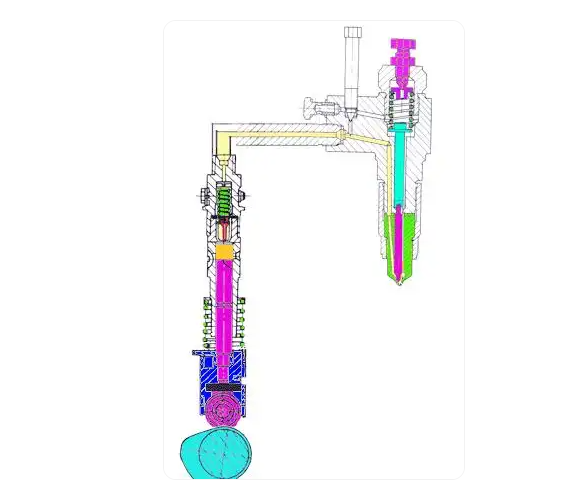

The fuel injector controls fuel injection through solenoid valve and cooperates with hydraulic servo system to optimize the injection process. When the ECU sends out the injection pulse signal, the solenoid valve inside the fuel injector will act accordingly to control the fuel injection in the high-pressure fuel rail.

◉ Characteristics of diesel engine fuel injection system

The diesel engine fuel injection system is the key component responsible for atomizing the fuel and evenly distributing it in the combustion chamber. The fuel injection system atomizes the fuel to ensure that the diesel and air are fully mixed to meet the design requirements of the combustion chamber. The fuel injection nozzle and the injector body constitute the system, and their installation position and angle need to be determined according to the design of the combustion chamber.

Development breakthrough of modern diesel engines

◉ Injection timing and pressure control

Compared with the traditional fuel supply method, the common rail injection fuel supply system adopts independent injection timing and pressure control to optimize the injection process. When working, the high-pressure fuel pump injects the fuel into the common fuel supply pipe at high pressure, and at the same time, the closed-loop control of the pressure sensor and the ECU is used to achieve precise regulation of the oil pressure in the pipe.

◉ Fuel economy and improvement measures

Compared with gasoline engines, diesel engines are more fuel efficient than gasoline engines, and their fuel consumption is usually more than 30% lower than that of gasoline engines. Through technological improvements, modern diesel engines are still continuously improving fuel economy while reducing noise and emissions.