Introduction of the Electric heating type DPF regeneration equipment

Introduction of the Electric heating type DPF regeneration equipment

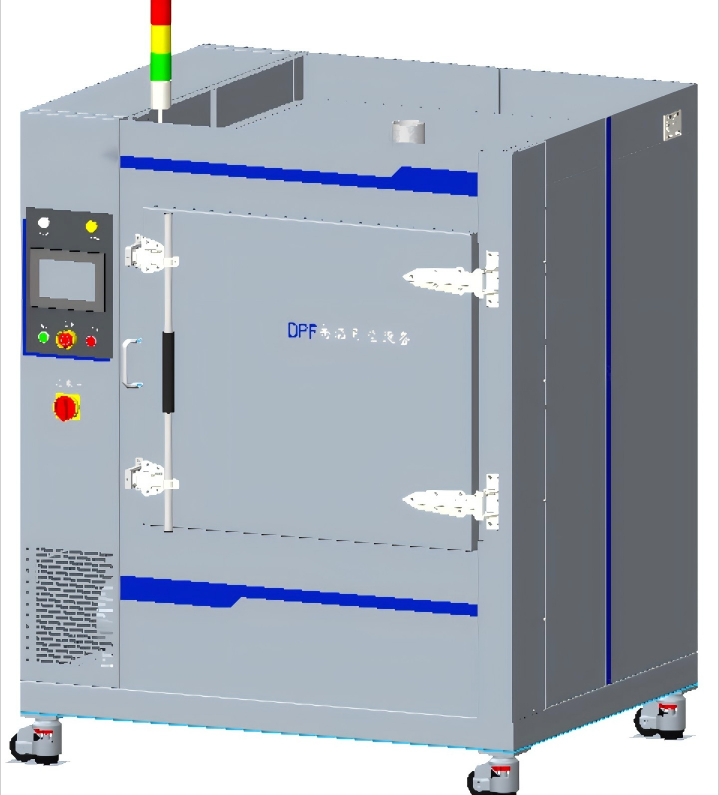

Electric heating type high temperature DPF regeneration equipment:

1. Exterior industrial design, atmospheric beauty;

2. Solid materials, the furnace wire is with high quality niobium iron chromium aluminum heating material, famous brand electrical components;

3. Large power, fast heating, large furnace space, can accommodate 4 maximum specification carrier regeneration at the same time;

4. Fresh air supply and oxygen, with pulse soot blowing system, high temperature regeneration efficiency;

5. Forced fresh air cooling and rapid furnace cooling can greatly shorten the regeneration time and improve the efficiency;

6. Electrical redundancy design protection, overload protection, phase break protection, etc., high safety factor;

7. Advanced regeneration strategy, which automatically calculates reasonable regeneration time for carriers with different parameter states;

Requirements for the use of DPF regeneration equipment:

Installation location requirements of DPF regeneration equipment:

Waterproof and moisture-proof;

with good heat dissipation and ventilation capacity;

the equipment should not be exposed to flammable or corrosive gases;

there must be a 2-meter clearance above the equipment.

power requirement of DPF regeneration equipment:

Electric heating type DPF high temperature regeneration equipment:

KL-DZL40 access wire adopts 25m m 2 RV copper wire;

KL-DZL 25 access wire adopts 16m m 2 RV copper wire;

KL-DZL 15 access wire adopts 10m m 2 RV copper wire.

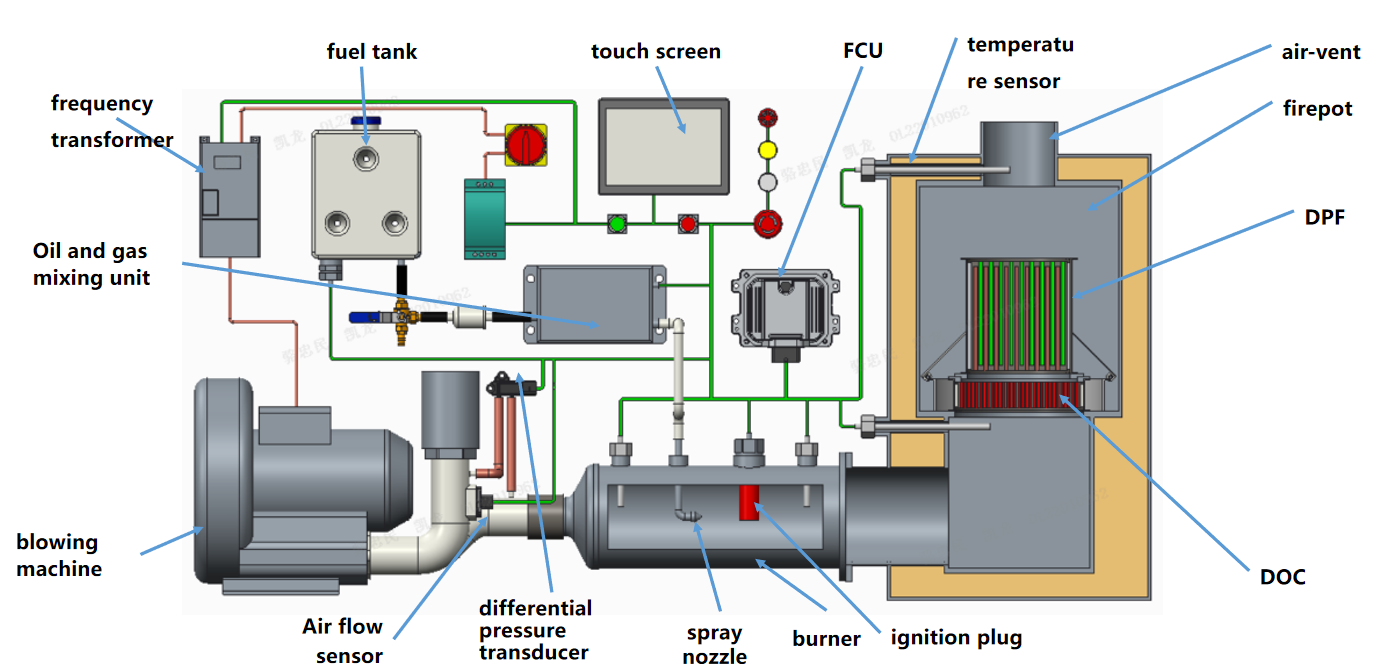

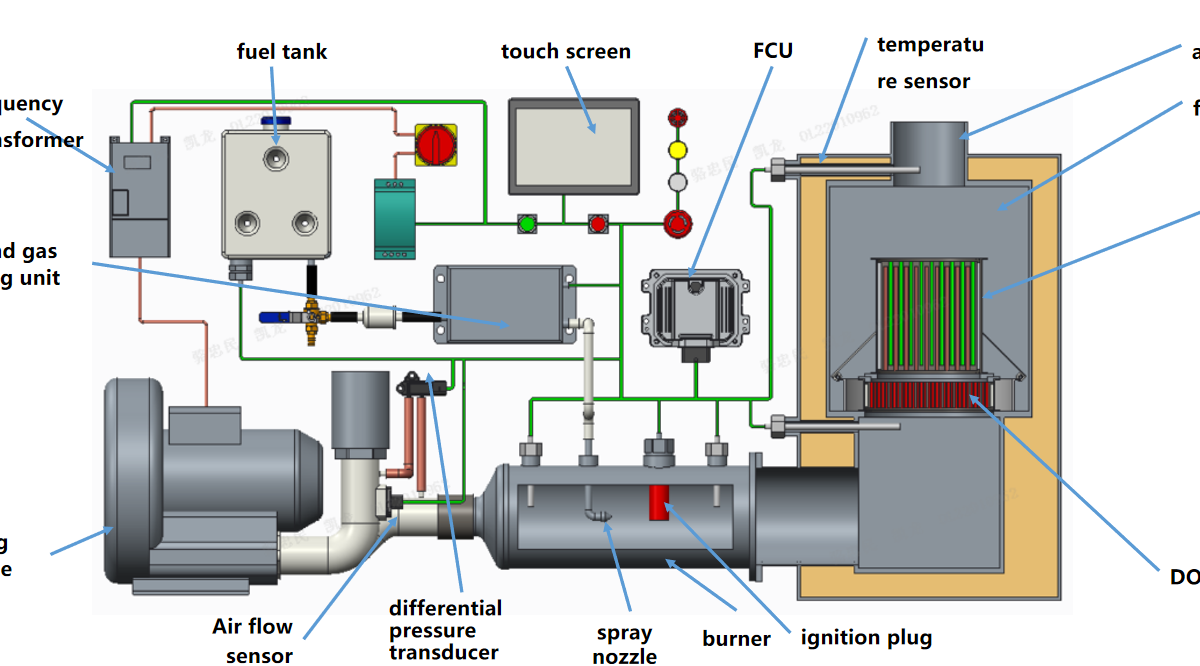

Standard DPF purge detection equipment/high temperature regeneration equipment with fuel heating:

conventional 220V mains electricity, access wire is 2.5 mm² RV copper wire;

the grounding terminal of the power socket should be reliably grounded.

Air source requirements of DPF regeneration equipment:

Connect clean compressed air of 6-8 kgf/cm 2.

Configure an air filter to remove water and impurities.

The air tube is a plastic or nylon tube with a diameter of ∅12;

the air volume requirement: flow rate ≥60L/min.