DPF Substrate Materials Guide: Lifespan, Regeneration & Best Practices

How Diesel Fuel Quality Affects Modern Emission After-Treatment Systems

DPF Substrate Materials Guide: Lifespan, Regeneration & Best Practices

What Is a DPF Substrate?

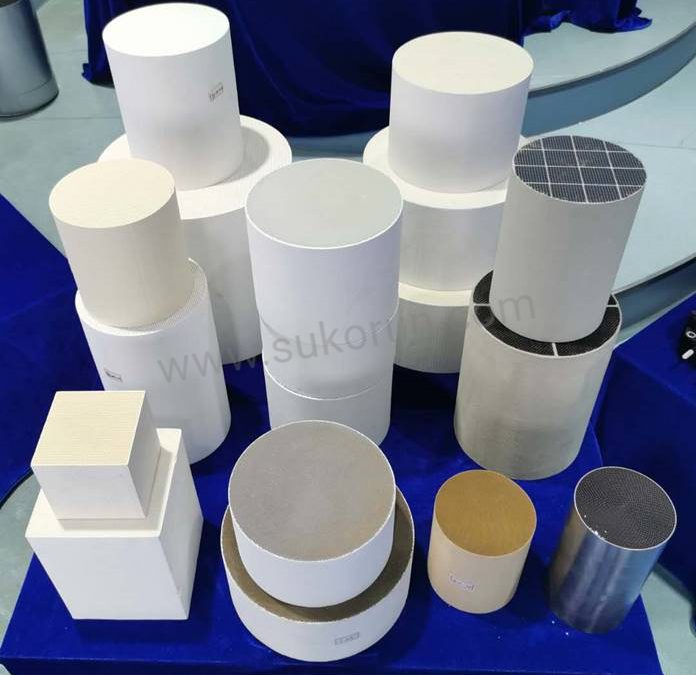

A DPF substrate is the “wall-flow” honeycomb structure inside the filter unit. Exhaust gases pass through the porous walls and soot is trapped. The substrate material must endure high temperatures, frequent thermal cycling during regeneration, soot and ash deposits, and chemical attack from exhaust components.

Common Substrate Materials & Their Characteristics

Cordierite (Ceramic)

Advantages:

Cost-effective and widely used.

Good for moderate duty cycles and lighter vehicles.

Disadvantages:Lower maximum temperature (~1200 °C) and weaker mechanical strength under extreme conditions.

More vulnerable to thermal shock and cracking when regeneration is aggressive.

Use Case: Light-duty diesel vehicles or moderate use where frequent high-temperature regenerations are not the norm.

Silicon Carbide (SiC)

Advantages:

Higher heat resistance, higher mechanical strength (strength found to be >2× that of cordierite in tests)

Better performance in heavy duty, frequent regeneration, or high soot‐load conditions.

Disadvantages:Higher cost, more complex manufacturing and sometimes special mounting/segment design due to high thermal expansion.

Use Case: Heavy trucks, off-road diesel machines, high soot/ash load environments.

Other Materials (e.g., Aluminum Titanate, Metallic Substrates)

Emerging materials such as aluminum titanate (AT) are being developed: they promise lower expansion coefficients and improved life, though they are not yet as widely used.

Lifespan & Regeneration Behaviour

What Determines DPF Lifespan?

The Material:Is it made of cordierite or Silicon Carbide (SiC)? The Cleaning Process:How and when is the soot burned off? The Driving Conditions:Is the vehicle used for city driving or long hauls?

Why Material Matters for Longevity

Passive Regeneration:Occurs automatically during normal highway driving. Active Regeneration:The vehicle triggers a cleaning cycle by raising the exhaust temperature, which is more demanding on the filter.

Best Practice: Matching Material to Application

Light-duty / urban vehicles: Cordierite is often cost-effective if regeneration events are moderate.

High mileage / heavy duty vehicles: SiC is preferred for durability and fewer failures.

Maintenance & monitoring: Frequent soot loading, short-trip driving, poor fuel quality accelerate filter degradation — regardless of material.

Regeneration control: Use engine control strategies, differential pressure sensors, temperature monitoring to optimize regeneration and avoid substrate damage.

Conclusion

The choice of DPF substrate material deeply influences durability, regeneration resilience, cost of ownership, and overall emissions performance. Cordierite serves well in moderate conditions; SiC excels under heavy duty and harsh regeneration cycles. Understanding these differences, aligning material to duty cycle, and implementing appropriate regeneration strategies are critical to achieving long, reliable service life.

With a solid grasp of material science and real-world duty demands, you can make informed substrate selections that support emission compliance and reduce lifecycle costs.

See DPF here