How Diesel Fuel Quality Affects Modern Emission After-Treatment Systems

How Diesel Fuel Quality Affects Modern Emission After-Treatment Systems

How Diesel Fuel Quality Affects Modern Emission After-Treatment Systems

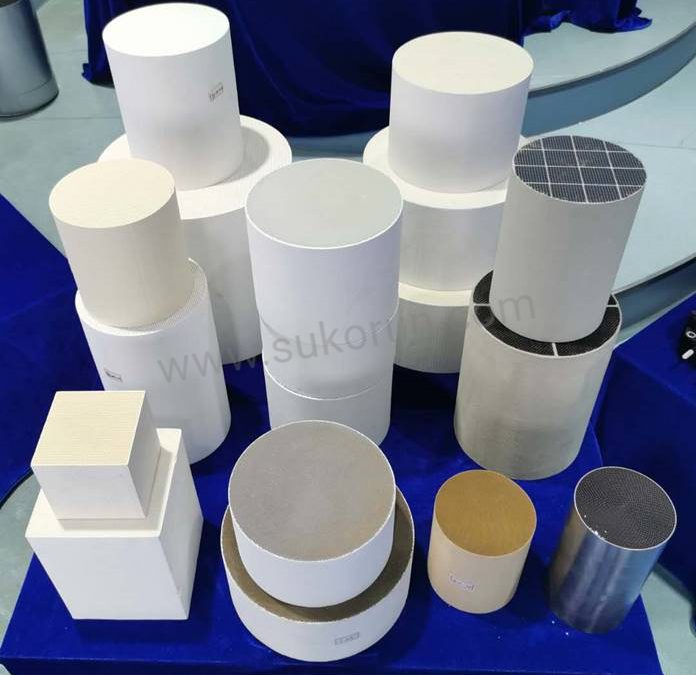

Diesel after-treatment technologies—DOC, DPF, and SCR—are designed to meet increasingly strict global emission standards. However, their performance and lifespan are closely tied to diesel fuel quality. Impurities such as sulfur, aromatics, water, ash, and metal contaminants can cause catalyst poisoning, substrate blockage, and regeneration failure.

This article explains how poor-quality diesel affects each system and outlines effective countermeasures.

1. Understanding Diesel Fuel Quality Issues

Based on technical findings from MECA, DieselNet, EPA technical reports, and SAE papers, the main diesel fuel quality concerns include:

High sulfur content

Leads to sulfate formation, catalyst poisoning, increased PM, and excessive ash.High ash or metal contaminants

Common from poor refining, lubricant additives (Ca, Mg, Zn, P), or fuel adulteration.High aromatic content

Produces more soot and raises combustion particulate formation.Water contamination

Causes injector issues, corrosion, and unstable combustion.Biodiesel blends with poor oxidation stability

Increase deposits and accelerate DPF loading.Adulteration with kerosene or low-grade fuel

Reduces cetane number, produces more unburned hydrocarbons and soot.

These issues directly affect all after-treatment substrates and catalysts downstream.

2. Impact on DOC (Diesel Oxidation Catalyst)

2.1 How Poor Fuel Quality Harms DOC Performance

Authoritative sources (EPA, MECA, DieselNet) consistently report:

Sulfur Poisoning

High sulfur forms sulfates and sulfuric acid, reducing the oxidation efficiency of precious metals (Pt/Pd).

This increases PM formation downstream, directly loading the DPF.

Aromatics & Unburned HC

High aromatic content increases HC and CO emissions, saturating the DOC and reducing conversion efficiency.

Metal Contaminants

Ca, Zn, Mg, P bind to catalyst surfaces and permanently reduce activity.

2.2 Effects on DOC Substrates

Cordierite substrates risk thermal shock from uncontrolled exotherms during regeneration.

Metallic substrates may suffer from corrosion if fuel contains water or acids.

3. Impact on the DPF (Diesel Particulate Filter)

3.1 Increased Soot Production

Poor combustion from low-grade diesel produces:

Excessive soot

Harder-to-burn particulate

Higher regeneration frequency

(Study references: DieselNet technical summaries; DOE/ORNL particulate characterization papers)

This accelerates thermal stress and cracks substrates.

3.2 Ash Accumulation

Ash is non-combustible. Sources include:

Sulfated ash from fuel sulfur

Lubricant additives (Ca, Zn, P)

Metallic contaminants

As MECA data shows, ash load is the primary long-term limiter of DPF life, filling channels and reducing filtration capacity.

3.3 Poisoning & Melting

Sulfur increases regeneration temperature → risk of melting cordierite substrates (melting point ~1200°C).

In severe cases, thermal runaway cracks SiC segments.

4. Impact on SCR (Selective Catalytic Reduction)

4.1 Sulfur Poisoning

SCR catalysts (Cu-zeolite, Fe-zeolite) are highly sensitive to sulfur:

Sulfur blocks active sites, forming Sulfate species, reducing NOx conversion.

EPA studies show prolonged sulfur exposure can reduce conversion efficiency by >50%.

4.2 Excess Soot & HC Slip

DPF failure causes HC and soot to enter the SCR, leading to:

Catalyst masking

Permanent deactivation at high temperatures

Increased ammonia slip due to poor NO/NO₂ balance

4.3 Metal Contaminant Poisoning

Metals such as Na, K, Ca deactivate the SCR catalyst, as documented in many SAE catalyst degradation studies.

5. Holistic Consequences for the After-Treatment System

Poor diesel quality causes a chain reaction:

DOC efficiency drops →

DPF soot increases →

Regeneration becomes more frequent and hotter →

DPF substrate cracks / melts →

SCR receives unbalanced exhaust (HC, soot, low NO₂) →

SCR conversion falls →

Fuel consumption increases and emissions exceed limits

This creates expensive failures across the entire system.

6. Practical Countermeasures & Engineering Solutions

6.1 Fuel-Related Strategies

Use reliable, certified low-sulfur diesel (<10–15 ppm sulfur).

Avoid adulterated or off-spec fuels.

Test diesel for water and metal contaminants regularly (ISO 4406).

Use proper fuel storage with anti-corrosion management.

6.2 Engine-Side Strategies

Maintain correct injection pressure and spray pattern.

Ensure air–fuel mixture control to reduce soot formation.

Maintain turbocharger function to ensure optimized combustion.

6.3 After-Treatment-Side Solutions

DOC: Use higher-load noble metal coatings in high-risk regions.

DPF:

Choose SiC or aluminum titanate for high-soot regions.

Conduct periodic ash cleaning according to OEM guidance.

SCR:

Use sulfur-resistant catalyst formulations (Cu-zeolite for high-temp stability).

Perform thermal desulfation procedures when necessary.

6.4 Monitoring & Calibration

Use differential pressure sensors to detect early soot increase.

Monitor NOx sensors to identify SCR degradation.

Use ECU calibration optimized for local fuel characteristics when possible.

7. Conclusion

Diesel fuel quality has a decisive influence on DOC, DPF, and SCR durability and performance.

High sulfur, metal contaminants, poor combustion stability, and adulterated diesel can lead to:Catalytic poisoning

Excess soot

Accelerated ash accumulation

Substrate cracking

Reduced NOx and PM control

Higher operating costs and downtime

By selecting high-quality fuel, maintaining the engine and after-treatment system properly, and using materials engineered for challenging environments, operators can ensure long-term emissions compliance and system reliability.