Diagnosis and Solutions for Common Vehicle Urea System Faults

Introduction

The vehicle urea system is a key component in reducing emissions from diesel vehicles. However, faults such as loss of power, abnormal urea consumption, and low urea pressure often occur during use.

Fault 1: Vehicle Lacking Power, Normal Urea Consumption

Common Phenomenon:

The owner reports reduced vehicle power, normal urea consumption, and a small amount of white smoke from the muffler during sudden acceleration.

Analysis and Solution:

Use a diagnostic tool to read fault codes, indicating “engine emissions exceed standards” with no other faults.

Remove the urea nozzle for an injection test; results are normal.

Inspection reveals severe urea crystallization and blockage in the high-temperature catalytic pipe, causing exhaust obstruction.

Clean the exhaust pipe and the ceramic surface of the catalyst, then replace the urea solution. After a test drive, the fault disappears.

Summary:

Urea crystallization accumulates inside the exhaust pipe, leading to restricted exhaust flow, reduced power, and excessive emissions. After several driving cycles, OBD may limit torque. This fault is often caused by substandard urea quality. It is recommended to use qualified urea solution and clean the urea system regularly.

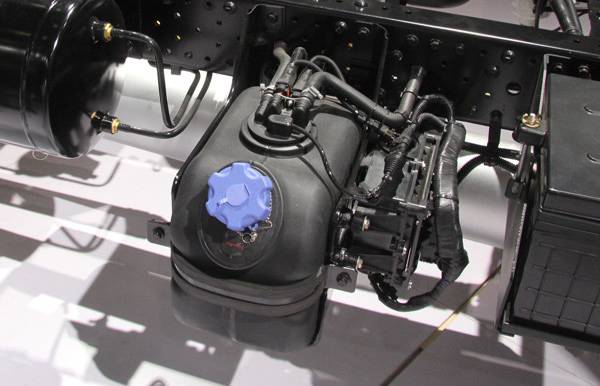

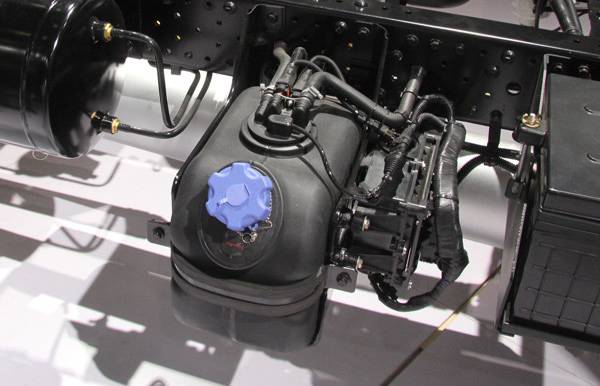

Fault 2: Low Urea Pressure, High Urea Consumption

Common Phenomenon:

The dashboard warning light flashes frequently, with fault codes indicating “low urea pressure” and abnormally high urea consumption.

Analysis and Solution:

Severe leakage is observed at the top of the urea tank. Replacing the urea tank and urea pump does not resolve the issue.

Inspection reveals leakage from the urea tank vent hole, ruling out overfilling of urea solution.

Further inspection of the water heating valve shows it is damaged and stuck open, causing excessively high temperature in the urea tank.

After replacing the water heating valve, the fault is resolved.

Summary:

High temperature in the urea tank causes urea to volatilize and escape through the vent hole, crystallizing and blocking it. Blockage creates a vacuum in the tank, hindering urea pump pressure buildup and triggering low-pressure faults. Regular inspection of the water heating valve and vent hole can prevent such issues.

Fault 3: Insufficient Power, Abnormally High or Low Urea Consumption

Common Phenomenon:

The warning light remains on, vehicle power is insufficient, RPM is limited to 1800, the SCR system fails to function, and urea consumption is abnormal.

Analysis and Solution:

Diagnostic tool reads fault codes including high voltage signal from the urea pump pressure sensor, short circuit in actuator 2, open circuit in the urea reversing valve, and sensor power supply 3 error.

Inspection reveals extensive corrosion in the urea pump power supply module, causing wiring short circuits and sending incorrect voltage signals to the ECU.

After replacing the urea pump and power supply module connectors, most fault codes can be cleared, except “sensor power supply 3 error.”

This fault code points to the ECU’s internal power supply module. Replacing the rail pressure sensor resolves the issue completely.

Summary:

Corrosion in the power supply module is a common cause of SCR system circuit faults, leading to signal transmission errors and affecting urea injection and system operation. Regular inspection of circuit waterproofing and anti-corrosion measures, along with timely replacement of damaged components, ensures stable urea system performance.

Conclusion

Urea system faults are often related to urea quality, component aging, or circuit issues. Regular maintenance, use of qualified urea solution, and timely inspection of circuits and heating valves can effectively prevent faults. For complex problems, it is recommended to use professional diagnostic tools and consult technical personnel to ensure vehicle emissions compliance and stable performance.