PRODUCTS

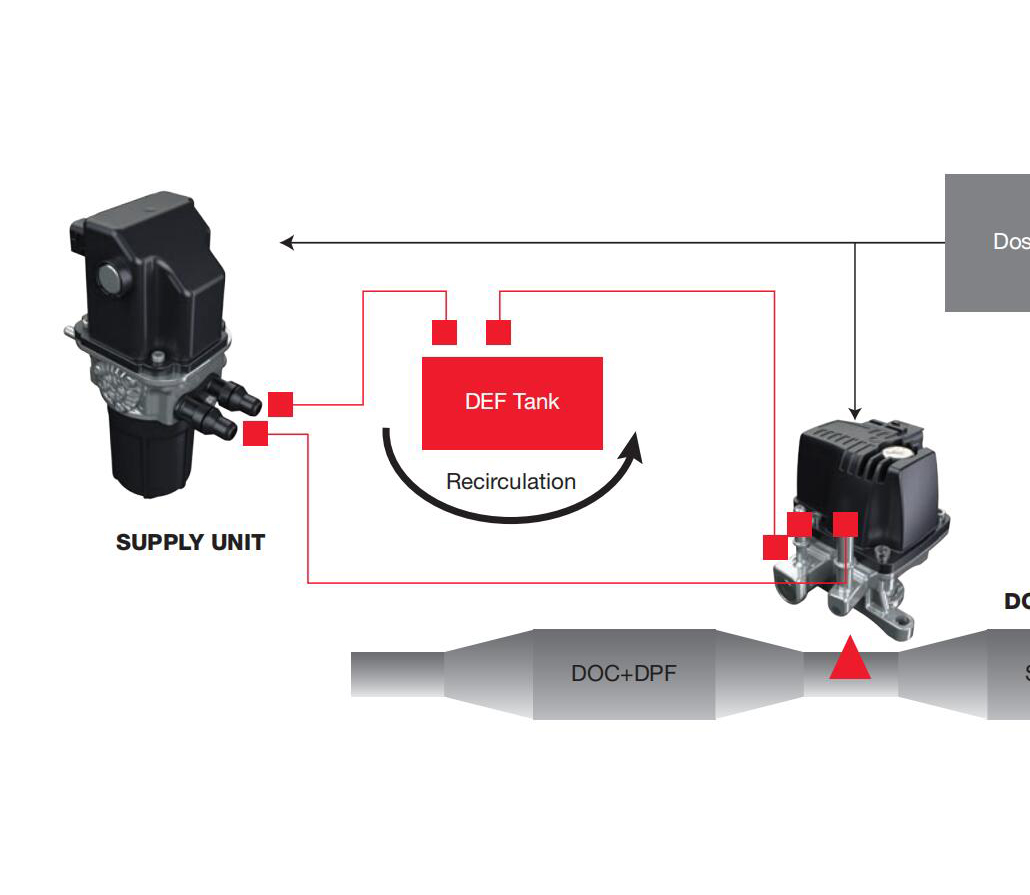

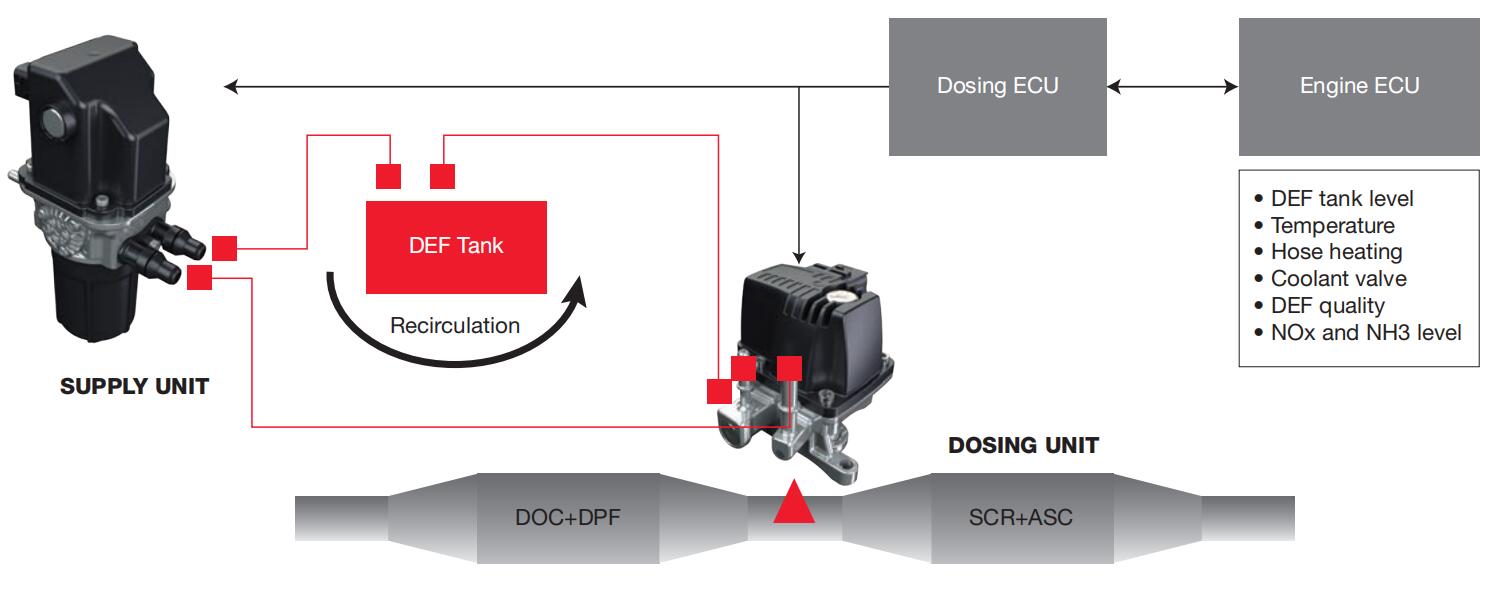

1.2 Emission After Treatment System for Cummins UL2.2 Urea Dosing System

Customized Emission After Treatment System for Cummins UL2.2 Urea Dosing System

Emission After Treatment System for Cummins UL2.2 Urea Dosing System

Emission After Treatment System for Cummins UL2.2 Urea Dosing System

We can customize the Emission After Treatment System for Cummins UL2.2 Urea Dosing System

Features:

COST FFICIENT DESIGN, State-of-the-art design for measurement precision, and lower current-consumption, Integrated motor-board,

Cooling is done by urea, no coolant lines are required.

Electronically controlled pressure relief valve (ePRV)

Flapper Valve Suction side damping for improved line disturbance resistance

Improved performance, efficiency and reliability

Flexibility and ease of integration

Frost resistant components for fast thaw

no power required post key-off and crystallization prevention

Safe shutdown – no purge necessary

Increased thermal capabilities:

– Ambient temperature limits up to ~+105°C

– Increased frost robustness

Plug connectors ensure debris-free assembly

12V and 24V options

Liquid only system with similar physical interface and flow capability as UL2 integrated aftertreatment systems that meet ever-higher demands for efficiency, durability and optimized performance levels for on-highway commercial vehicles and off-highway heavy equipment markets.

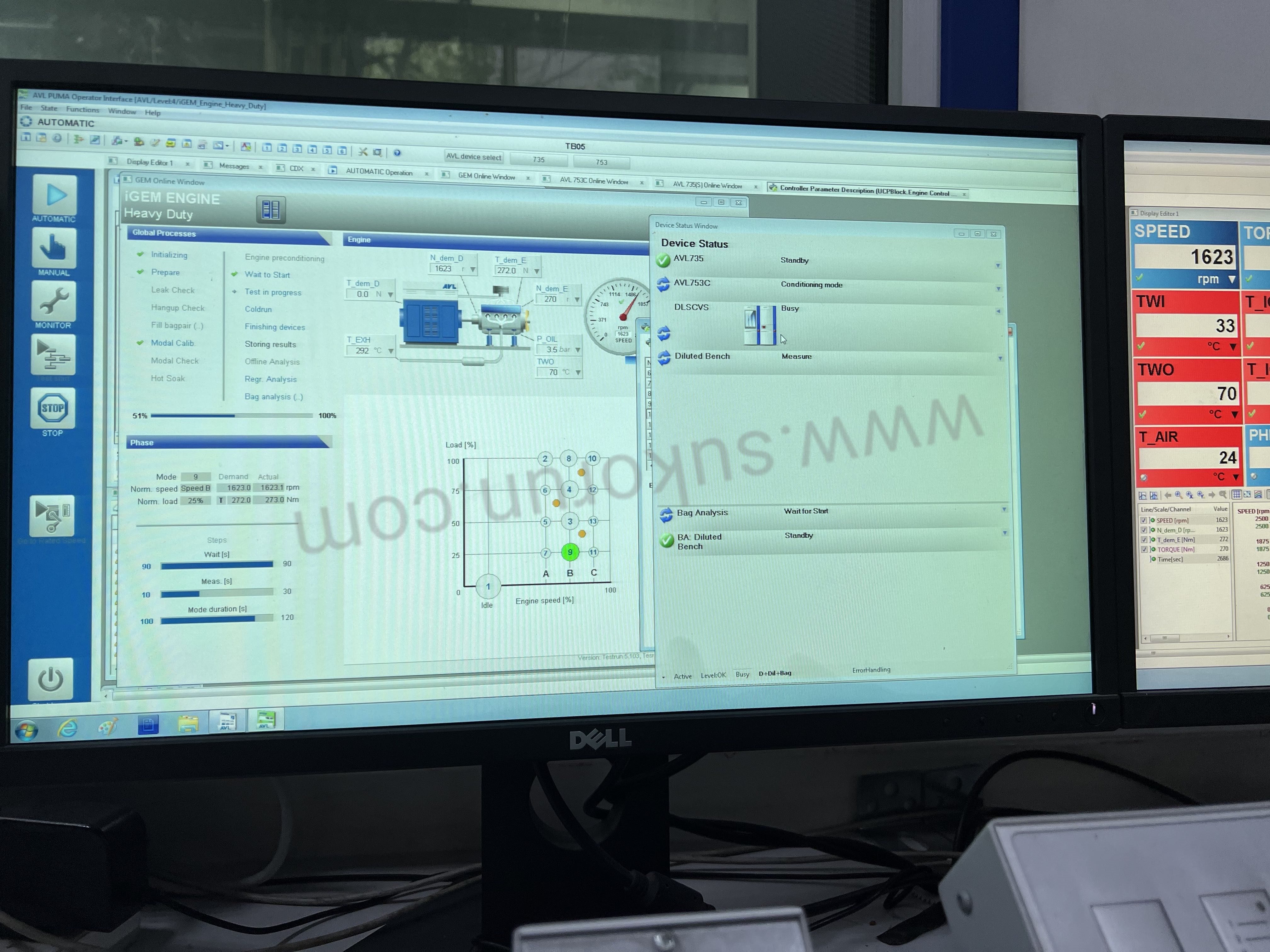

R49 test

R49 test

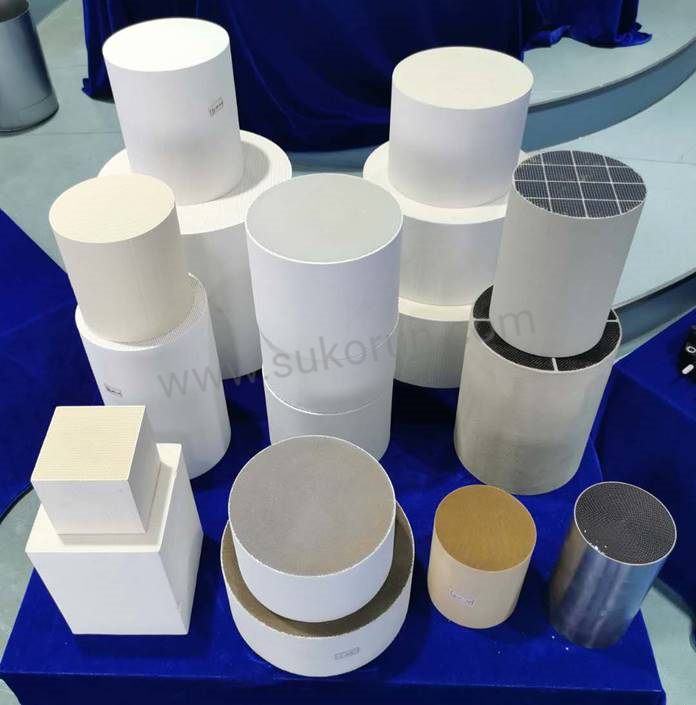

SCR DPF

Contents Example (Varies according to different requirements)

1×dosing pump

1×dosing injector

2×T-sensors

2×NOx sensors

1×exhaust flowmeter

1×refilling pump

1×backpressure sensor

1×level sensor

Each wire harness is 15m

Find out more other After treatment parts, please click hear.